xoxoxoBruce • Mar 13, 2017 11:52 pm

Anything you can do they can do better,

They can do anything better than you.

Not you, humans. They are computers used to design things, especially 3-D printed things.

The computer calculates the stresses, knows the material's strength and calculates what is needed.

Fine, but what is the calculation using for data? Tables somebody gave it? Are the accurate?

If you tell it to design for maximum weight savings you get a design the is just strong enough for the parameters it's given.

If you tell it to program for low cost it depends on the data for a safe design.

I can see a lot of slaves in this woodpile. :eyebrow:

link

They can do anything better than you.

Not you, humans. They are computers used to design things, especially 3-D printed things.

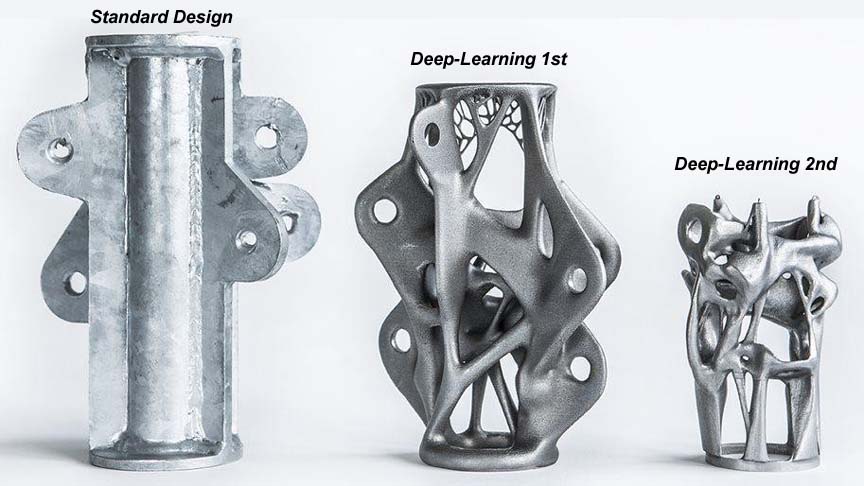

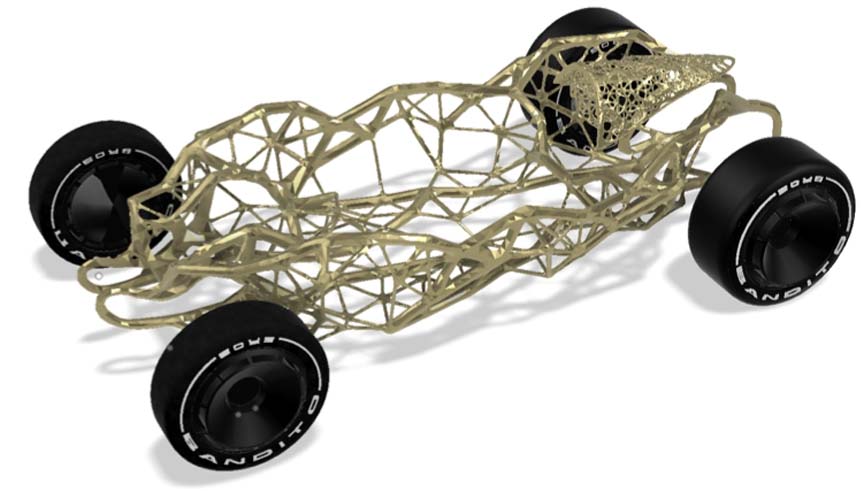

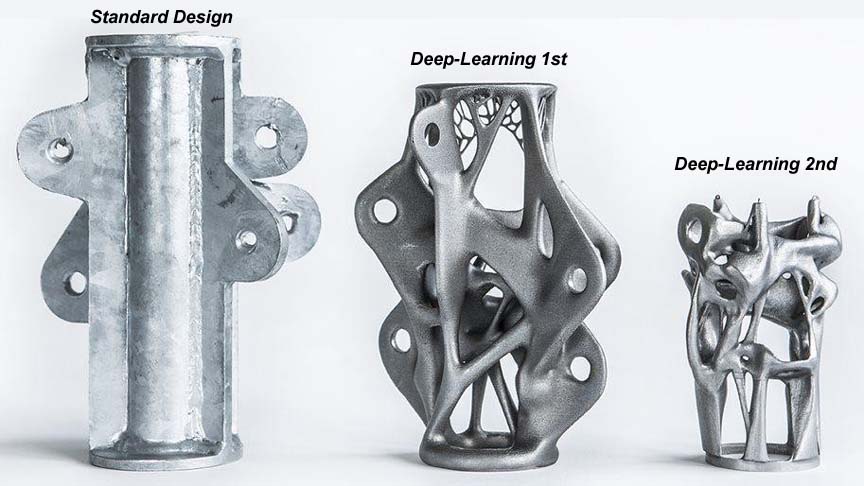

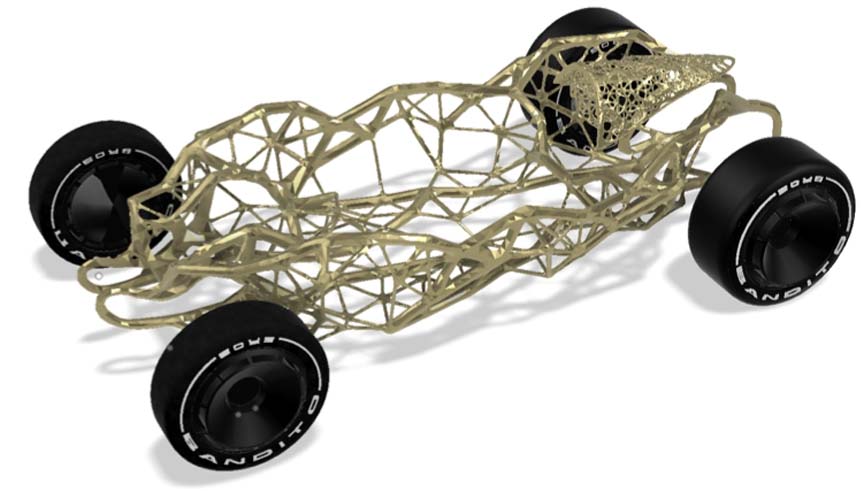

What happens when you have Deep Learning begin to generate your designs? The commons misconception would be that a machine’s design would look ‘mechanical’ or ‘logical’. However, what we seem to be finding is that they look very organic, in fact they look organic or like an alien biology. Take a look at some of these fascinating designs.

“This is not only an exciting development for the construction sector, but many other industries as well. In the case of this particular piece, the height is approximately half that of one designed for traditional production methods, while the direct weight reduction per node is 75%. On a construction project that means we could be looking at an overall weight reduction of the total structure of more than 40%. But the really exciting part is that this technique can potentially be applied to any industry that uses complex, high quality, metal products.”

The computer calculates the stresses, knows the material's strength and calculates what is needed.

Fine, but what is the calculation using for data? Tables somebody gave it? Are the accurate?

If you tell it to design for maximum weight savings you get a design the is just strong enough for the parameters it's given.

If you tell it to program for low cost it depends on the data for a safe design.

I can see a lot of slaves in this woodpile. :eyebrow:

link