My First Knife

I completed my first knife during a bladesmithing class I took last week.

I'm pretty proud of it, despite the flaws. The most obvious problem with the knife is that the handle is made to fit my hand and the blade is undersized in comparison. I could go back, fix it and then spend another couple of hours refinishing it so it looks nice again.

I think I'll keep it around as-is to remind me of my mistake.

The whole album of pictures that were captured during the process are

here.

Anyway. I'll call out a few of the pictures and provide some commentary.

I forged out 3 blades on the first day of class. Two hidden tang blades and one full tang blade. The full tang was set aside early on due to time constraints.

Here are the two hidden/stub tang blades after they've been rough ground and heat treated and then cleaned up after the heat treat.

This is one of my favorite parts: hand finishing. I'm sanding out 400 grit scratches with 600 grit Rhynowet paper.

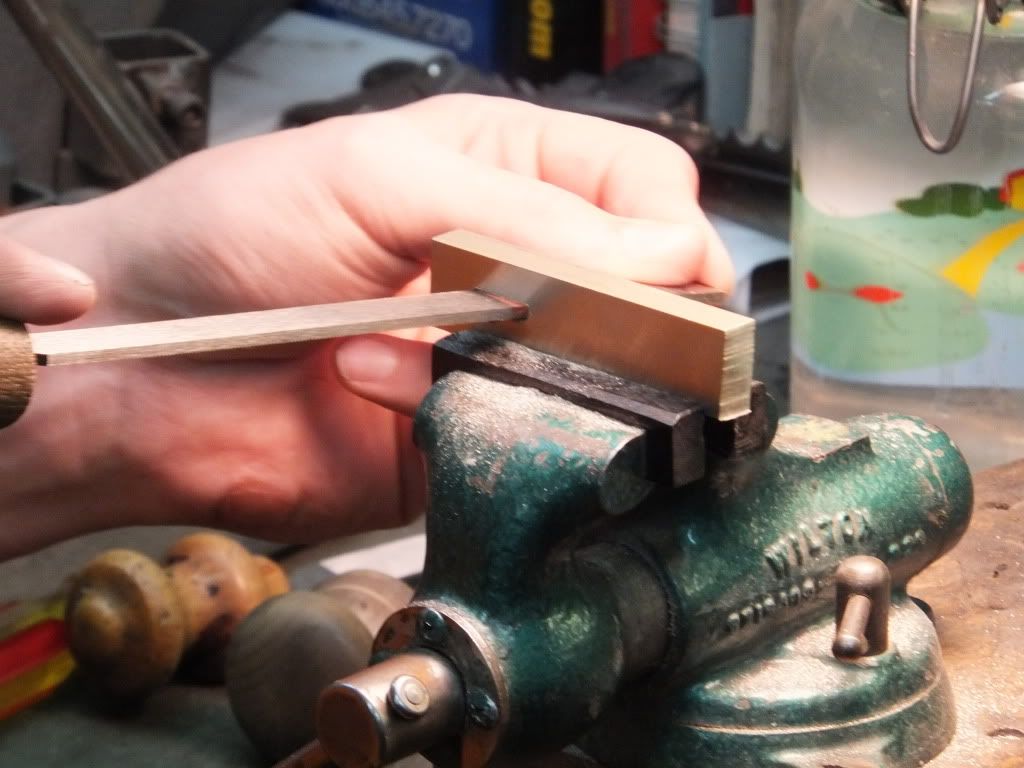

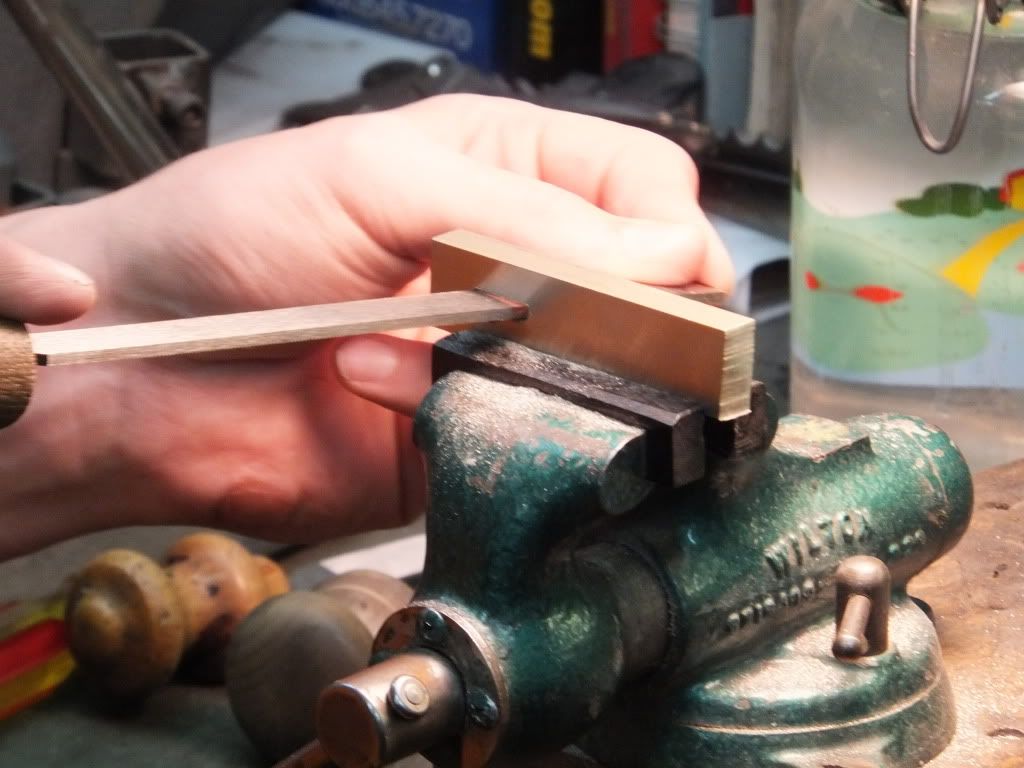

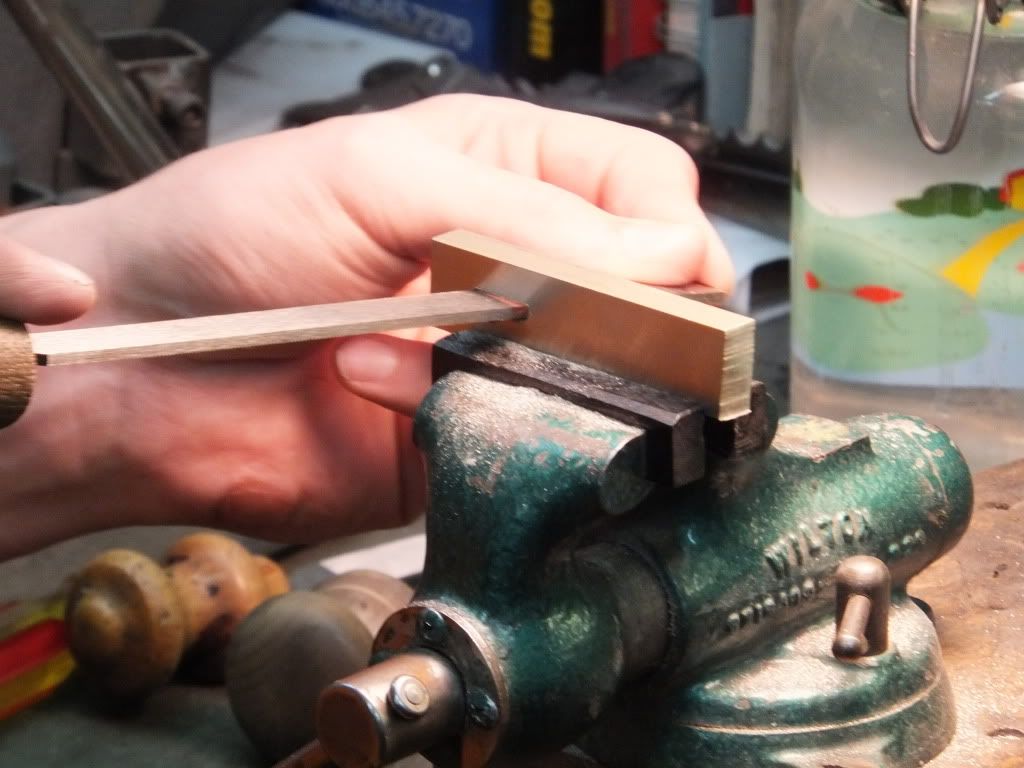

Here I am filing the shoulders off so that the ricasso and guard fit together without gaps. The file guide has a layer of carbide on top to keep the file from destroying it.

After the blade is filed and sanded to 600 grit. I etched the blade. This is done to show up any flaws in the blade, especially for a newbie maker like me. The etching brings out any remaining < 600 grit scratches, among other flaws.

Filing the guard nearly drove me insane. You really can't see what you're doing...

At this point the guard has been fitted to the blade, the handle material has been drilled out and it's all been stuck together with Acraglass.

When that is hard, you take it back to the grinder to shape the handle. Then you hit it on the buffer and you're done, aside from sharpening the blade...

Sorry about the huge pictures. I'll see if I can figure out how to resize them with GIMP...

I, for one, like these huge pics.

It's beautiful, Perry.

I was surprised that your hands weren't more beat up.

Verry cool , dont worry about the big pics , they show detail

cool skill to have. +5 points to you

Okay, I'll leave the big pictures since ya'll like them. They are relatively small bandwidth-wise.

For the curious, this knife is composed of:

Nickel (aka German) silver guard

1084 steel

Honduran Mahogany

cool skill to have. +5 points to you

I figure if the end of the civilization comes about, I can make weapons. It's a relatively cushy job compared to fighting off zombie hordes.

I was surprised that your hands weren't more beat up.

The majority of the damage to my hands was done while forging on the first day. I developed a huge blister on the heel of my hand. In a few weeks or months it will develop into a thick callus.

A couple of ancient Chinese secrets I learned last week: Vaseline will keep epoxy from sticking to something. Windex will neutralize ferric chloride. This particular type of mahogany smells like a mocha when you're drilling and grinding it.

How do I place an order? I have an urgent want.

Very cool. I'm one of the main whingers about oversized pics, I find those fine, thanks for sharing :)

Excellent work! Do you know how many hours you have into it?

Excellent!

I definitely would like to place an order for two. I'm thinking Christmas for my boys.

Let me know what I need to do - pm is good.

Absolutely gorgeous, Perry.

Your work is excellent and I, for one, like the progress pictures, especially the large ones. As for the proportions of the knife, that's a good set of proportions. A handle that fills the hand is a good size, and a blade about the width of your hand is plenty of blade. You have a well proportioned knife there.

Did you start with blanks or did you create them from flat stock? The guard looks like stainless steel in the finished picture, but in the filing picture it looks like a block of copper or maybe a block of micarta. For the full tang blade, do you intend to make some through rivets to secure cheek pieces for the handle? Or something else? What other handle materials do you have in mind?

O look at me, such a chatterbox. Your knife is a piece of art, Perry. You have a lot to be proud of. I look forward to more pictures and stories from you, and maybe a knife of yours for my own someday.

The most obvious problem with the knife is that the handle is made to fit my hand and the blade is undersized in comparison. I could go back, fix it and then spend another couple of hours refinishing it so it looks nice again.

This knife wasn't made to sell was it? Or to hang on the wall as a piece of art? The handle fits your hand, and the blade is long enough to do what you want it to do. Why is this a problem? I'll take function over appearance.

It's a beautiful knife, you should be proud of it.

Is that a bucket full of wet sparks underneath the belt grinders? Clever! Also, nice clamp/vise. Your instructor has a nice shop, and I can clearly see that he's given a lot of thought to the finish product, especially on the glamour shots.

Wow. I'm thrilled by all the appreciation you all are expressing. Thanks for all of the encouragement.

Classic. Foot3. I haven't really given any thought to selling knives yet. I'd be happy to make whatever you'd like, as long as it's in my power.

I'll PM you guys and we can talk more about details.

Is that a bucket full of wet sparks underneath the belt grinders? Clever! Also, nice clamp/vise. Your instructor has a nice shop, and I can clearly see that he's given a lot of thought to the finish product, especially on the glamour shots.

Yeah. Those buckets really help with the sparks and wood particles. There's even a vacuum hose to suck wood dust away on one of the grinders.

Ed's knife vise is awesome. It's got rubber padded jaws/clamping area and rotates so you can get at three sides of your blade without taking it out. A little design flaw keeps it from going all the way around.

It's a beautiful knife, you should be proud of it.

I am very proud of it. It just that with all physical artifacts, there is always room for improvement. I want each of my knives to be better from a design and functional perspective than the last.

There's an intimacy you feel with a handcrafted artifact. I've always heard craftsmen talk about it. It is an amazing feeling.

Did you start with blanks or did you create them from flat stock? The guard looks like stainless steel in the finished picture, but in the filing picture it looks like a block of copper or maybe a block of micarta. For the full tang blade, do you intend to make some through rivets to secure cheek pieces for the handle? Or something else? What other handle materials do you have in mind?

I started with 1.25x0.25 stock and forged the blade by hand. I did "cheat" and draw the tangs down with the power hammer and hydraulic press. (Funnest tools ever, btw.) That's a luxury I won't have in my own shop, and will probably add an hour's worth of forging to a hidden tang blade.

Nickel silver is all copper but for just enough nickel to make it silver. I think that's what might be showing on the surface of the raw guard stock. Nickel silver mirror polishes really, really easy. 400 grit and then buff it.

For the full tang I'll be using pins or rivets of some sort. Most likely nickel, stainless or brass depending on the particulars. Titanium is another popular pin stock.

I've got a few pieces of deer and stag antler to use for handles. I'll also do micarta, g10 and carbon fiber. I really want to try homebrew micarta. Oh, yeah, I also have some dyed camel bone that I think is going to come out REALLY cool.

There's a black spacer between the guard and the handle. It's made from vulcanized paper.

Excellent work! Do you know how many hours you have into it?

I have little idea. We worked back and fourth between three different blades. There was also a lot of instructional and bullshitting time.

Since I'm not doing it for a business, I probably won't pay much attention to the time investment right now. I need to keep my focus where it matters.

Again, I have to thank you all for the kind words and encouragement and interest in my work.

The knife looks great. That over-size handle will pay off in blade control.

Good job!

The knife looks great. That over-size handle will pay off in blade control.

Good job!

Great knife perry.

Thanks!

The knife looks great. That over-size handle will pay off in blade control.

Good job!

Exactly right, my missing knife has a large handle which makes it awesome for all kinds of stuff when it isn't missing.

A year or two ago I found a Spyderco Meerkat whilst hiking. Look at the proportions between the

handle and blade.

(I'd post an image, but I'm hotlink-shy.)

Mine is just like that, except it's made in Golden of 440C, instead of Aus-6 from Seki City.

I also have a Boker Chad Los Banos

Subcom F, which has interesting proportions.

us humans love us some patterns:

more on inlay banding

This guy has an amazing catalog:

http://www.inlaybanding.com/products.htmlA year or two ago I found a Spyderco Meerkat whilst hiking. Look at the proportions between the handle and blade.

(I'd post an image, but I'm hotlink-shy.)

Mine is just like that, except it's made in Golden of 440C, instead of Aus-6 from Seki City.

I also have a Boker Chad Los Banos Subcom F, which has interesting proportions.

Those have tiny handles. I'd be curious to see how they feel in my (large) hands.

This is an enormous thread from one of the knifemaking forums I frequent.

It's a work-in-progress thread that details the entire knifemaking process. It goes to show you why custom handmade knives easily go for thousands of dollars.

This is an enormous thread from one of the knifemaking forums I frequent.

It's a work-in-progress thread that details the entire knifemaking process. It goes to show you why custom handmade knives easily go for thousands of dollars.

Damn. That is amazing. I was going to post a few pictures of a dorky knife I made in school, but it would be an insult to knifemaking.

149 posts into the thread at this point. OUTSTANDING Perry, thank you. I noticed it took 113 posts to generate the first set of questions. I, too, am fond of WIP threads. This one is especially wonderful. I'm super envious of the guy's shop. Of course, this is his professional work (I'm guessing) so he can justify it more easily than I can. I can also sympathize with the specific moans about the difficulty and the extra trouble it takes to photo document one's own work. I have numerous projects I've done this for, and some of them have made it to the cellar. This guy's cook's tour through the shop of a master knifemaker is thrilling for me. I give him a standing ovation. You'll do well to read stuff like this. I know you have just as much potential as he's demonstrating. Go get'em, tiger!

Damn. That is amazing. I was going to post a few pictures of a dorky knife I made in school, but it would be an insult to knifemaking.

bull shit. Post them, *please*. I like to see what work my friends do. you're a damn renaissance man anyhow, you have nothing left to prove, just show us the pictchurs man.

149 posts into the thread at this point. OUTSTANDING Perry, thank you. I noticed it took 113 posts to generate the first set of questions. I, too, am fond of WIP threads. This one is especially wonderful. I'm super envious of the guy's shop. Of course, this is his professional work (I'm guessing) so he can justify it more easily than I can. I can also sympathize with the specific moans about the difficulty and the extra trouble it takes to photo document one's own work. I have numerous projects I've done this for, and some of them have made it to the cellar. This guy's cook's tour through the shop of a master knifemaker is thrilling for me. I give him a standing ovation. You'll do well to read stuff like this. I know you have just as much potential as he's demonstrating. Go get'em, tiger!

I'm envious of all of the big fancy tools he's got. His disc grinder, surface grinder, milling machine, salt pot, etc. are all things I want to have some day. But what really blows me away is his attention to his own personal process, which gives rise to all of the crazy custom jigs and tools he's built.

His trick with the jeweler's saw is brilliant (around post 210). And like most brilliant things it's obvious after you see it done once.

I'm flattered that you think I have that sort of potential. I'm so nervous about the three knives I've committed to make for dwellers. I know I can do it, but that emotional component is still a hurdle.

bull shit. Post them, *please*. I like to see what work my friends do. you're a damn renaissance man anyhow, you have nothing left to prove, just show us the pictchurs man.

I have to second this.

My knife wouldn't have turned out half as good if I weren't being baby-sat by a world-class knifemaker. It also would have taken twice as long in my ill-equipped shop.

I was disappointed that he tried to fill the void with superglue. And then tore off the handle. I would have tried shellac stick, it can be used to mimic figured grain by using different colors much the same way the damascus is done. Otherwise I'd consider inlaying a design in silver or gold or ivory or mother of pearl or something. That would make it seem intentional, it could also be a counterpoint to the single rivet. He could have cast a small decorative concho or whatever you call it.

Just my .02 as a creative problem solver who hates to do things twice.

Since I am an attention whom are, here are some photos of my knife made about 16 years ago.

The steel is from a coil spring we scavenged at an auto junk yard. We used leaf springs for wood turning tools and froes and axe heads and such. the coil spring was straightened and flattened then roughly shaped, and sandblasted. There are still a lot of files marks and grinder marks.

The guard and pommel were first made in wax and then cast in

Brittania Metal which I then dimpled with a tiny ball peen hammer that I made out of a grade 5 bolt that I ground and polished.

The handle is from some walnut from a 200 year old tree that that was cut down to make way for a hospital. My teacher and his friend brought a chainsaw mill to the building site and took away most of the trunk. A friend and I got to keep some of the larger branches (8-12 in diameter) I still have some of it sawn into bowl blanks. I just expoxied or bondo-ed the handle and pommel on.

I have no idea of the rockwell hardness but a file has to be pretty new and sharp to bite the steel. After looking at Wheeler's process I see how I did a lot of things out of step causing me problems later.

Maybe I will sharpen it. The handle is a bit slim for my hand.

One of the pommel. Not sure that is the right name, but whatever.

Those have tiny handles. I'd be curious to see how they feel in my (large) hands.

I carry a Spyderco Dragon fly ,

Small Knife that fills my large hands ,

Weird at first until you start working with it

foot3 - that's awesome and you were how old?

Well done footie.

Amazing thread PW and keep the links coming guys, this is really interesting stuff.

Great knife, Foot!

This thread is interesting, and the timing is good too. My son wants to make a knife, but I have no real tools for it. Plus, I don't allow him to use power tools yet. I showed him where I have a scrap bar of steel, and where the hack saw and files are. He filed on that bar for about 60 seconds before giving up. In 7 years he will be old enough to join the local blacksmith club and use their shop.

Until then, I guess he will have to stick to wood. He's made 3-4 wooden swords so far. I should take a picture of his latest. It's actually pretty good. A half lap joint holds the guard on, and the sword is nice and sharp on the edges with a blunt tip and an carved handle.

Cool knife, F3.

This thread is interesting, and the timing is good too. My son wants to make a knife, but I have no real tools for it. Plus, I don't allow him to use power tools yet. I showed him where I have a scrap bar of steel, and where the hack saw and files are. He filed on that bar for about 60 seconds before giving up. In 7 years he will be old enough to join the local blacksmith club and use their shop.

How old is he? Do you have to be 18 to join the club?

If you find a smith to talk to, he might have your son in to get some hands on learning. I've read in knife magazines about kids as young as 8 forging and finishing knives (with strict adult supervision).

They do have blades you can buy and then just finish them from there. It's a lower barrier to "making a knife." The kit blades go from simple fixed blades to complex folders. Most of them let you mix and match handle materials, pins, bolster, etc.

I've heard good things about

Knife Kits and

USA Knife Maker.

Also, if the steel is not annealed it's going to be significantly harder to cold work.

Pretty sure you have to be 16 to join the local blacksmith club. He's 9 now. He's had a pocket knife for 2 months, so he's not even a seasoned pro at using a knife yet, let alone making one.

But those kits look like a good idea. Maybe a Christmas present for him.

Wow, what a beautiful piece of art.

Well done.

Pw Check this dude out

Part 1

[YOUTUBE]gLlObpob6lg[/YOUTUBE]

Part 2 (bigger so you can see detail )

[YOUTUBEWIDE]2f01tU9akqY[/YOUTUBEWIDE]

Wow - that was really neat.

I was watching the first vid and thinking ,

Why is he twisting all that Metal ???

And whats up with all the little plates ???

then he started grinding and I was like Oh ,, thats Why !!!

That is fascinating to follow thru the entire process.

It's at the 10' mark of the 2nd video that the whole process makes sense.

We've all read the poem, but these 2 videos bring it to life.

Under a spreading chestnut tree

The village smithy stands;

The smith, a mighty man is he,

With large and sinewy hands;

And the muscles of his brawny arms

Are strong as iron bands.

Thanks for posting

Very cool. Thanks zippy!

I can't imagine how difficult it is to keep that much steel straight.

I need to get back in gear with the hot work. It's been too cold lately to do anything else in the shop.

This is an enormous thread from one of the knifemaking forums I frequent.

It's a work-in-progress thread that details the entire knifemaking process. It goes to show you why custom handmade knives easily go for thousands of dollars.

Oh thanks ya prick, you just cost me 3 hours of my beauty sleep. ;) :lol:

You don't need no more beauty, Bruce.

Oh thanks ya prick, you just cost me 3 hours of my beauty sleep. ;) :lol:

Glad to know I'm not the only one who was hooked and had to read the entire thing.

Yeah, when he found that flaw in the handle it damn near made me physically ill.

<---- twice.

Glad to know I'm not the only one who was hooked and had to read the entire thing.

Had a little accident in the shop. Should have use of my hand back in 3-4 more weeks.

Here's a WIP thread I was jonesing over today:

http://www.customknifecollectorsassociation.com/vbulletin/showthread.php?t=1674

Really cool D-guard bowie with a stars and stripes pattern damascus blade.

:eek:

Will it gain full function again?

[YOUTUBE]K8JkB-OR7H4[/YOUTUBE]

Had a little accident in the shop. Should have use of my hand back in 3-4 more weeks.

Here's a WIP thread I was jonesing over today:

http://www.customknifecollectorsassociation.com/vbulletin/showthread.php?t=1674

Really cool D-guard bowie with a stars and stripes pattern damascus blade.

The guy uses his power screw-driver as a simple lathe. Freaking brilliant. I'll probably end up dead if I try it.

you should check out some of the crazy shit boatbuilders do.

Thank you for Accidents Will Happen.

There isn't enough Costello on YouTube.

Knew this whole album by heart.

I lie. I knew it by half - the flip side was scratched...

Thank you for Accidents Will Happen.

There isn't enough Costello on YouTube.

Knew this whole album by heart.

I lie. I knew it by half - the flip side was scratched...

Elvis is the shiznit.

Here's a tame one: note the zip tie on the trigger

[YOUTUBE]TsD1Tz06-9U[/YOUTUBE]

I was leaning away from the display of the computer as I watched that, waiting for the shaft of the drill bit to burn through that two by four and fling the mast through my screen like a powered caber toss.

It almost looks like he has a dowel chucked in the drill that is then fastened inside the mast. As long as they are epoxied together and spin as one unit than it might be pretty safe from any kaber tossing movements.

:eek:

Will it gain full function again?

Yeah. My buffer grabbed a knife and flung it at me. Luckily I got most of my body out of the way and the blade didn't smack me pointy-end first. I broke 3 bones in my hand and had some cutting and bruising. Painful, but recoverable.

Yikes! Do you have a new plan for buffing?

Yikes! Do you have a new plan for buffing?

Yup. I'm going to build an armored shell that will keep things from making the circuit.

What happens with most buffer accidents is that the buffer grabs the work piece and either throws it away from you (damages a wall or something) or the work piece goes all the way around and directly into you. If you build a metal cover for the back and top of the buffer then work pieces will get stuck/deflected in there. Worst case it fucks up the piece or the buffing wheel.

Now I just have to save enough for a welder and a couple of other misc tools so I can fabricate it. Nothing off the shelf will work for my setup.

Yikes! Do you have a new plan for buffing?

Subcontract it, is my vote.

I saw a video of a guy sandblasting well-used epee parts to clean them up for a rebuild. He had a nice little plexiglass booth built around the blaster with heavy rubber (?) gloves mounted inside. I wonder if you could contain the whole unit to save your garage from shrapnel?

Yikes! Do you have a new plan for buffing?

Subcontract it, is my vote.

Or, you could use your backup hand.

I suppose his off-hand is getting stronger now that its attending Morningwood.

Perry, I had to remove hella rust from one of those Damascus blanks the knife fairy sent me and completely removed the pattern. I gave it a bath in muriatic acid and the pattern re-emerged but rather faintly. I suppose there is a special sauce they need to be dipped in. Any pro-tips?

Do you know the composition of the damascus? 15N20 and 1080+?

If the billet contains nickel (as in 15N20) use ferric chloride (usually available at Radio Shack for PCBs in 35% concentration). 4:1 water to etchant.

You have to start with the billet VERY clean. Use 409 or Windex. Then air dry it very well.

Then repeat the following process until the pattern is visible:

1. Hang in the etchant for 5 minutes. It should not be in contact with any surface in the

2. Neutralize the acid with windex or tri-sodium phosphate solution.

3. Scrub off the oxides with 2500 grit paper or #0000 steel wool.

I'm not really familiar with what to do with muriatic. I've heard 50/50 water to acid and 10:1 water to acid. Some people add hydrogen peroxide as a kicker to make it work faster (do not inhale this shit).

Hope that helps.

Thanks, will give it a try. The composition is a mystery.

hopefully it went smoothly and looks groovy...

ftfy

Had a little accident in the shop. Should have use of my hand back in 3-4 more weeks.

Here's a WIP thread I was jonesing over today:

http://www.customknifecollectorsassociation.com/vbulletin/showthread.php?t=1674

Really cool D-guard bowie with a stars and stripes pattern damascus blade.

Can you make a rough estimate what it would cost to have a unique knife like that, made by a big name maker like White?

And I AM sorry about your finger.

I bet it was groovy!

That cuts me to the quick.

Damn, Perry. That is a sick knife. I'd bet 7-8 grand at least. I've got no idea how many hours are in it though.

The etching of the blank has been added to the job rotation. May be a few weeks yet before I can get to it. I stole a chunk of wood from your care package to make scales for it. Not to worry, there is still plenty left for you.

I should have a WIP pic to show here in a couple of days. I bought two dozen various clamps and have been able to do a bit of work with some thought.

Can you make a rough estimate what it would cost to have a unique knife like that, made by a big name maker like White?

I'm with F3 on the price. No less than $4-5k and as much as $8k. Maybe as high as $10-$12k depending on how much of a name John White is. (I don't keep up with the collector market.) It is a full-on art knife. It will not be used. Never. Okay, it might if you are very rich or you are just slicing scraps of paper.

John probably has at least 40 hours in that knife, and probably more like 60-80. Then there is time for the sheath maker and inlay/engraver. I don't have much idea how long those two things take, but I wouldn't be surprised if the total number of hours on this knife didn't top 120 hours.

You can easily bring the price down if you compromise on the blade (pattern, not quality), engraving and sheath. I bet you could get a nice usable d-guard bowie for about $1k. That would have a simple sheath, plain steel blade and stainless fittings.

Here's a load of cheap porn. Minimal story, mostly pictures:

http://forums.dfoggknives.com/index.php?showforum=2From a link on that pr0n site of yours.

You know how people say "Ooh, I want one of those."? Well, I need one of these:

[VIMEO]37360333[/VIMEO]

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

--pause, regrip--

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

...

ahh... I'm done chopping wood now.

start carrying water, then.

But there's a hole in the bucket, dear martha, dear martha.

I'm with F3 on the price. No less than $4-5k and as much as $8k. Maybe as high as $10-$12k depending on how much of a name John White is. (I don't keep up with the collector market.) It is a full-on art knife. It will not be used. Never. Okay, it might if you are very rich or you are just slicing scraps of paper.

Thanks, those prices are believable, but I think 40 hours is way short, 120 is believable since he had to start over when he was way along with the blade.

Slicing paper, or perhaps Mr. Boddy in the Library.;)

From a link on that pr0n site of yours.

You know how people say "Ooh, I want one of those."? Well, I need one of these:

[VIMEO]37360333[/VIMEO]

I want to do that when I grow up.

I want to do that when I grow up.

That was awesome.

You know how people say "Ooh, I want one of those."? Well, I need one of these.

Very cool. I'm pretty impressed that the axe head was constructed traditionally. A lot of folks just make the entire thing out of steel, instead of splitting mild steel and welding in steel at the edge.

Making some hammers and axes is on my list of things to try, when I can find some room in the supplies budget.

I've been making a few nails here and there to practice hammer control. It takes me 5-10 minutes for each one. Fun and good practice, but those nails are expensive!

People used to burn down their cabins when they moved so they could collect the nails for the next cabin they'd build.

People used to burn down their cabins when they moved so they could collect the nails for the next cabin they'd build.

That reminded me of Jonathan Nedbor. He came to teach at a local blacksmith workshop last year. His home/shop is in High Falls, NY. He is a student of Dutch Colonial ironwork.

He talked about this and how nails retrieved this way would be straightened by children.

Unfortunately he has no web presence. If you are ever down in his neck of the woods, I would stop by.

I'm trying to get my children to sort my miscellaneous fasteners into broad categories. nails, screws, bolts. They are pretty good, but the attention span isn't there. Maybe I should put an audio book on for them...

People used to burn down their cabins when they moved so they could collect the nails for the next cabin they'd build.

and to light the way forward, eh?

[YOUTUBE]q6iO_HpT4F4[/YOUTUBE]

and to light the way forward, eh?

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

--pause, regrip--

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

whack

...

ahh... I'm done chopping wood now.

"Chopping wood", eh? That what you teenagers are calling it nowadays? :jagoff:

I've got the first of two knives for classicman finished, packed and ready to ship tomorrow. It's going to BigV for a sheath.

When I've got my pennies lined up, I want to start making my own sheaths. I think I'll start with Kydex/thermoform sheeting sheaths. Which leads me to the next round of porn. Covering up that naked steel:

http://www.dorsetwoodlandblades.co.uk/howtokydex.htm

(Warning: These are somewhat in-depth, from what I've watched so far.)

Hope you don't mind that I'm sharing the first...

I am so psyched! I'm getting one for each of my sons.

Yeah. That's totally cool. I mean to have my wife take some semi-pro shots of it, but got it boxed up before she had a chance.

I bet we'll get some pictures during the sheathmaking process too.

Pics from BigV? Ya think????? lol

Just maybe. But I'm thinking since it'll involve sharp implements it's pretty much a given. If he had to hang from a chandelier and use power tools there'd be no question.

Where the hell is he anyway?

That must be some interview he's having.

He knows we have knives and shit to talk about too.

Just maybe. But I'm thinking since it'll involve sharp implements it's pretty much a given. If he had to hang from a chandelier and use power tools there'd be no question.

someone make a spot for this boy in the hall of fame. That there is some dry humor.

He couldn't zip his fly without injuring himself.

Several of those look like Randall Made Knives. They started making knives before WWII. Now they are highly prized collectors items.

http://www.randallknives.com/Time for some Guy Clark

Randall Knife

My father had a Randall knife

My mother gave it to him

When he went off to WWII

To save us all from ruin

If you've ever held a Randall knife

Then you know my father well

If a better blade was ever made

It was probably forged in hell

My father was a good man

A lawyer by his trade

And only once did I ever see

Him misuse the blade

It almost cut his thumb off

When he took it for a tool

The knife was made for darker things

And you could not bend the rules

He let me take it camping once

On a Boy Scout jamboree

And I broke a half an inch off

Trying to stick it in a tree

I hid it from him for a while

But the knife and he were one

He put it in his bottom drawer

Without a hard word one

There it slept and there it stayed

For twenty some odd years

Sort of like Excalibur

Except waiting for a tear

My father died when I was forty

And I couldn't find a way to cry

Not because I didn't love him

Not because he didn't try

I'd cried for every lesser thing

Whiskey, pain and beauty

But he deserved a better tear

And I was not quite ready

So we took his ashed out to sea

And poured `em off the stern

And threw the roses in the wake

Of everything we'd learned

When we got back to the house

They asked me what I wanted

Not the lawbooks not the watch

I need the things he's haunted

My hand burned for the Randall knife

There in the bottom drawer

And I found a tear for my father's life

And all that it stood for

Found a couple of versions of the song on youtube. Very touching.

Several of those look like Randall Made Knives. They started making knives before WWII. Now they are highly prized collectors items.

I thought he looked pretty proud, and I think he represents the egalitarian quality of knife collecting. A guy doesn't have to buy the Purdey shotgun of knives, to collect. Every price level can be a collection, and the knives that you make, are always a goal.

I thought he looked pretty proud, and I think he represents the egalitarian quality of knife collecting. A guy doesn't have to buy the Purdey shotgun of knives, to collect.

Exactly. Randall Knives aren't fancy. They are special because of sentiment (Pops tells stories about how he killed a dozen Nazis with his!) and utility, not fancy engraving, wood or whatever.

Exactly. Randall Knives aren't fancy. They are special because of sentiment (Pops tells stories about how he killed a dozen Nazis with his!) and utility, not fancy engraving, wood or whatever.

Is your Pops' name

Bud, by any chance?

Probably the same rhetorical Pops.

I went out to the shop to grind. Flipped the switch on the grinder and got an error light on the controller. Something shorted out according to the "slow blink" light. Haven't been able to figure out what yet.

Hoping it's still in warranty. The controller was $600 and the motor was $250. Not looking forward to replacing them after virtually zero use.

Bummer. I hate sinking money into stuff that doesn't work...

5160

7" OAL

SS pins

I cannot remember what kind of wood I used. Smelled almost like cinnamon as I was working it.

Wow! That's really amazing. Very nice.

I've got the first of two knives for classicman finished, packed and ready to ship tomorrow. It's going to BigV for a sheath.

When I've got my pennies lined up, I want to start making my own sheaths. I think I'll start with Kydex/thermoform sheeting sheaths. Which leads me to the next round of porn. Covering up that naked steel:

http://www.dorsetwoodlandblades.co.uk/howtokydex.htm

(Warning: These are somewhat in-depth, from what I've watched so far.)

Pics from BigV? Ya think????? lol

Just maybe. But I'm thinking since it'll involve sharp implements it's pretty much a given. If he had to hang from a chandelier and use power tools there'd be no question.

Paging V... Paging BigV.

Honduran Rosewood or Elm.

Wow! That's really amazing. Very nice.

Seriously! Nice work.

Thanks all.

This one is for my grandpa's birthday. I tried my hand at a sheath. It came out pretty mediocre. Definitely a whole different skill set that I'm not quite ready to dive into.

Can't wait to get started on the next one.

7"?

Very nice work, sir. Proud, you should be.

•spoken in to my phone

So I have two knives in the pipe. They are the last two I need to do for other people. One is for classic, and is going to put the other one I sent to shame. The other is for a friend.

I think I'm going to quit making knives for a while after those are done. I don't have the time (read: not willing to sacrifice other things) to make the endeavor worthwhile. I think I'll refocus on my software development skills and work toward some more interesting things in that arena.

I find that I will take up a hobby and run with it for a while, and then get bored after too much focus in it. But it usually comes back. Or something similar.

It's about time for me to build a canoe. Or two. It's a lot to bite off though.

I find that I will take up a hobby and run with it for a while, and then get bored after too much focus in it. But it usually comes back. Or something similar.

It's about time for me to build a canoe. Or two. It's a lot to bite off though.

This is true. Not the canoe, though, not for me. The obsessive knitting has squeezed out the obsessive concertina playing. I wish I could do both at once.

Sent by thought transference.