a photoblog of what i did today.....

a place where you photoblog your day or major project of any field. carpentry plumbing electrical automotive. any DIY job....(never know....someone might need the info someday....)

today was two projects. on the Fixed Or Repaired Daily my goal was to change the front rotors and brakes as well as a bad cam position sensor located under a bunch of shit you had to remove to get to on the right front side of the engine. a real PITA. I did the front end first. first pic here is the tight fit into the shop today and go kart limited space in which to work...

truck 1

truck 1 by

plthijnx, on Flickr

the new rotor:

truck 2

truck 2 by

plthijnx, on Flickr

the doohickey you put the rotor on cleaned off with a shop rag. make sure you put a thin coat of grease on it before putting the rotor back on.

truck 3

truck 3 by

plthijnx, on Flickr

remove the wheel bearings from the old rotor, bathe them in gasoline then pack them with grease...

truck 6

truck 6 by

plthijnx, on Flickr

the best thing since sliced bread for this project... a bearing packer...

truck 7

truck 7 by

plthijnx, on Flickr

then with your bearings packed and in the new rotors you're ready to put them on...

truck 4

truck 4 by

plthijnx, on Flickr

new rotor on with brake mounting assembly.

truck 5

truck 5 by

plthijnx, on Flickr

done. put the tire back on and hit the road.

cam position sensor was a helluva lot harder and i was impatient so the blackberry sat on a go kart for that job. but i did take this one..the old sensor on the left cuisine-arted by the cam

truck 9

truck 9 by

plthijnx, on Flickr

so put ur projects here. even needlepoint. anything that you've done and you're proud of doing yourself....

ty sir. both were easy compared to the transmission swap! :D

Now you can go and stop. :D

Now you can go and stop. :D

right on and since i don't have to fly it (thank god it's not a plane with a old motor) i can drive it. keeping it running, albeit expensive lately, has really given my spirits a lift. times been bad my friends. everyone here has been a tremendous help. thank you.

Nothing like getting shit done to improve your outlook on life.:D

Nothing like getting shit done to improve your outlook on life.:D

couldn't have said it better myself!

plthijinx, the whole thing looked like a PITA. I use to love to work on my vw's because they were mechanically simple. Now you need a degree in mechanical engineering to fix more modern trucks and cars, and all the electronic bs to do it.

I've replaced worn calipers on disk brakes before, but haven't done the rotor before. Do new rotors normally come with new wheel studs included?

I've replaced worn calipers on disk brakes before, but haven't done the rotor before. Do new rotors normally come with new wheel studs included?

fortunately mine did. some do and some don't from what i understand...

plthijinx, the whole thing looked like a PITA. I use to love to work on my vw's because they were mechanically simple. Now you need a degree in mechanical engineering to fix more modern trucks and cars, and all the electronic bs to do it.

no kiddin'! i think even the sensors have sensors!! :3_eyes:

what was going to be only about a 6 tile replacement in the bathroom wound up being a "fuck it, lets redo the whole thing"

tile 1

tile 1 by

plthijnx, on Flickr

prybar was the sliced bread tool for the demolition:

tile 2

tile 2 by

plthijnx, on Flickr

a little more prep work and it's off to homo depot for hardy board and the tile store for tile mortar and grout.

tile 3

tile 3 by

plthijnx, on Flickr

Nice, plt. I wish I had the skills to do stuff like this. I can clean the tile, but I can't tear it out and replace it.

Home projects I can do. Auto repair I leave to someone else. Great pics and flickr photos pjinx.

thanks kero... it's not that hard. tearing up stuff can be fun sometimes and is usually easier than the re-install!

ty merc! the automotive stuff i'm going to have to agree there. i just can't afford to pay someone right now to do the work for me. the transmission? they wanted 650 bucks to just swap them out if i brought them one. $1800 to rebuild the one i had.

Well, I guess I wouldn't trust myself not to mess something up. I always wanted to learn to install tile, because I had these cool ideas about making mosaic floors in bathrooms. It's the tearing out that I have hesitated about.

The husband does the vehicle repair, though he doesn't always like to. Had to replace a water pump in one of our vehicles a month ago and it was a nightmare I guess, but we saved 600 bucks.

prybar was the sliced bread tool for the demolition:

I have a Tile remover tool for my roto hammer, BBBRRRRZZZZZZZZ!!!

KeroCase Most of the Bigger Homo depot type places have classes that are free or cheap .

Dive in GIRL!!! get yer hands dirty !!!!

I wish people would post there pictures rather than linking them from a host site. It's aggravating to go through old threads and read comments about red X's. Just sayin'...

goddamnitsonofbitchshit.

the new cam sensor is talking to me. only a matter of time before i replace it again. first i have to figure out why it's eating them up. if i have to replace the dummy distributor that's going to be a major major project. :mad2:

what i mean by talking is this. sounds like you've got an all night gerbil on a wheel.

dig in kero. taking up the tile takes the least amount of time per project specs usually. right now the roommate is cutting the hardy board and laying it down while i'm cooking diner. (chili with fresh Roma tomatoes, garlic, oregano and jalapeño peppers. oh and a beer of course! beer's got water in it right?)

edit: yeah i'd rather replace the cam sensor than a water pump. know the hubby went through a lot of shit changing that out. hell i'd rather do the front brakes 3 times over than tackle a water pump. but would take the water pump over the transmission replacement. i need a new rear seal on my engine. going to have to do the tranny one more time. sigh. oh well. hindsight 20/20. note to self and all others. when doing a major major job, replace as many seals as you can while you have the access to them.

I wish people would post there pictures rather than linking them from a host site. It's aggravating to go through old threads and read comments about red X's. Just sayin'...

should i replace and repost them? you can see them can't you? just making sure...my html is rusty.....

the tile replacement job just got bigger. the wall in between the bath and sink area's bottom boards are rotten. may have to tear out and replace the whole wall. hope not.

Water , the Home owners Best asset and their Worst enemy

Gots to contain it or keep it out or deal with the consequences

The Deeper you dig the worse it is

As they say in TX YEEEEHHHHAAWWWW !!!

nah i say "YEEEEHHHHAAWWWW !!!" when i lose an engine on take off :D nah roommate is hoping we only have to replace the molding and a little bit of a 2x4. nah not gonna happen. sink/cabinets have to come out and replace the wall IMO. the base 2x4 that the wall sits on is what's rotten. then again this is on the second floor. so what else is rotten?

should i replace and repost them? you can see them can't you? just making sure...my html is rusty.....

Naw, it's OK, I see them, I'm just thinking ahead.

If you need a rear main, it could be from excessive end play, worn thrust bearings. If the crank is walking, it could be causing the cam to walk too. Doesn't matter if the cam is chain or gear driven, unless it's got a thrust retainer, it can walk with the crank. Something to think about.

Naw, it's OK, I see them, I'm just thinking ahead.

If you need a rear main, it could be from excessive end play, worn thrust bearings. If the crank is walking, it could be causing the cam to walk too. Doesn't matter if the cam is chain or gear driven, unless it's got a thrust retainer, it can walk with the crank. Something to think about.

ok something to think about. would it be advisable to go ahead and replace the motor? 170K mileage that i know of

You could put a dial indicator on it, and check the end play, or drop the pan (shudder) and check the thrust bearings. If you have access to a good motor, it might be time to cut bait.

ouch. feeling that. was talking to a life long friend who is ASE. he recommended changing the dummy distributor b4 the engine but you make some very good points. damn. don't want that monkey.

Don't let me talk you into jumping the gun. I'm just throwing out possible causes for what you've experienced, that don't make it so. There are other possibilities to explore before you give up on that motor.

right on and the purpose for this thread. help others and let them learn from their experiences.....and get a little help along the way...

i sure as hell don't want to do an engine swap. but if i do and i win the lottery i will coat the truck in gold.

If you win the lottery, get a new truck... one with a buxom chauffeur and a keg. ;)

I'm liking the buxom chauffeur idea. What does them go fer? Besides guys in gold-plated Ferds...

google buxom chauffer with safe search off and see whatcha get! ahem. nsfw.

slept in this morning but when i woke up the roommate had already dug into the wall. very lucky here. wasn't near as bad as we thought.

If you win the lottery, won't you be buying a plane?

very lucky here. wasn't near as bad as we thought.

Cool Now give it a good Spray of Bug spray ( Prolly dont Need it ,But Hey its Open ) and seal it up

If you win the lottery, won't you be buying a plane?

ohhhh you betcha!

edit: prolly one of

these used to fly one until the half owner crashed and burned it.

well the hardy board is in and the cutout closed back up. didn't think to spray in there though zip. enough on the job today. have to go to work now. roommate will finish it up tomorrow.

i apologize for missing out on the actual laying out of the tile, grouting, etc. but i had to work. here is the end result. when laying the tile be sure to use spacers for an even *ahem* lay.

Wow, that looks really nice, plt. It appears you are a good *ahem* layer (of tile, that is!)

:thumb: Nice job, very classy.

G'day All,

This was my day, 16th December 2010, All water related, all taken West of Brisbane, within about 50km of each other:

Brisbane's Wivenhoe dam is at capacity for the first time in years, these are shots of the spillway gates, with only one of five gates open:

Secondly, a site visit to a country waste water treatment plant, where the main tank is in need of concrete repair:

Finally, an afternoon Summer storm forced me to pull over on the way home; this is through my windscreen.

And yes, I know I haven't posted in ages, but I've lurked a bit, and this thread caught my eye, here 'tis!

Fred, any time you get bored, come visit me! I have a list of projects that I cannot do alone. Several on the Cougar, and several more on the house. And two on the camper.

lol alright brian!

cool pics hagar! dam's are a work of art imo. been to hover dam twice and i'd go again!

okaaaay. here's the next project. (where the hell are they coming from and why do they find me??) at the go-kart track today we moved the carport over about 6 inches for better sidewalk access for customers. after that we busted up the front curb at the exit for the go karts from the pit. we are going to pour concrete and taper it down to grade.

in pic #4 we have to cut the rail with a cutting torch about 2 inches past the concrete you see there

in pic #5 i drilled a tap hole in the concrete to fasten the rail to the concrete. pic #6 is bob giving me support while i drilled the hole for the anchor bolt. pretty nifty gadget the bolt is. you hammer it in and then tighten down the nut. when you tighten the nut the ass end of the bolt flairs anchoring it in place. pic #7 is using the cutting torch to make an anchor hole in angle iron for the rails. ok pic #8 here is 1X1 (??) angle that we welded bolts to for anchor support when we pour concrete. the angle is going to be installed on both the inside and outside of the sloping down curb.

and finally in pic #9 here we're cutting down the existing rail prepping it for the downgrade and tapering. far as we got today. more tomorrow.

Fun Fun Fun !!!

From some body Who has to run a rotohammer Way to much , they work Best when the hammer inside has room to do its thing , as in if yer drilling straight down Sitting on the rotohammer don't work so well , Keep a hold of the drill and Some Pressure on it , But the RotoHammer should be able to Bounce a Bit ,

think of it Like this , when yer driving a Nail with a claw Hammer you draw the hammer BACK to put some Muscle into the Hit , same thing with a rotohammer

here's a couple minute vid of cutting the rail...

railFun Fun Fun !!!

From some body Who has to run a rotohammer Way to much , they work Best when the hammer inside has room to do its thing , as in if yer drilling straight down Sitting on the rotohammer don't work so well , Keep a hold of the drill and Some Pressure on it , But the RotoHammer should be able to Bounce a Bit ,

think of it Like this , when yer driving a Nail with a claw Hammer you draw the hammer BACK to put some Muscle into the Hit , same thing with a rotohammer

yeah i figured that out today. true dat!

oh and here is a tour of our racing facilities!

[YOUTUBE]iCkWh28jcAw[/YOUTUBE]

at the beginning of the vid you can see what our end result of the curb at the front of the pit is supposed to look like

alright day two and job nearly complete. pic 1 is where we left off yesterday. today we cut the rail on the right side that was bent and replaced it with a straight piece. then we set the other angle steel on the right there making sure it was level or nearly so. then we cut plywood to anchor to the sides for the concrete form. next we made some more stakes for the rebar and added the rebar and secured it with the rebar strap wire thingys. handy little gadget. wood handle with a swivel hook. you put the wire around the intersection of rebar, put the tool on the two eyelets of wire, move your hand in a circle motion and your done. go to the next one. then after we finished that we mixed and poured 11 bags of concrete and formed it in. total job time: 10hrs.

when the concrete cures we'll then remove the plywood forms and then sand down the steel and paint it.

You're one busy man. great photo blogs!

ty! looking back over the last 35 days or so i have been real real busy.

changed the transmission on the truck

built a deck at work in our outside party area

put new front rotors and brakes on the truck as well as the cam position sensor

helped the roommate with the master bathroom tile

and finally this curb project.

next week is electrical. friend has a trailer that is scarily rigged up so he has power down one wall. i've taken a peek at it. gonna be a tricky job. going to have to start at the power panel and chase the circuit down to find the problem. have to remove every switch and outlet and check for continuity. should be fun!

looks much better than when you started. Now it's a jump!

funny you mention that!every now and then some dumb ass will come into the pit when the ride is over and twice the car port has been nailed! the second time was with a double seat car. yeah they not only bought a go kart ride but a pole too.

So do you own an amusement park or something?

nah my good friend and flying buddy does. i started working for him year ago last september when i quit working at the flight school/charter biz. i'm trying to get back into engineering or aviation but the economy sucks balls still so....

here is a link to our web page

Houston Grand Prix if you'd like to check it out.

Naw, it's OK, I see them, I'm just thinking ahead.

If you need a rear main, it could be from excessive end play, worn thrust bearings. If the crank is walking, it could be causing the cam to walk too. Doesn't matter if the cam is chain or gear driven, unless it's got a thrust retainer, it can walk with the crank. Something to think about.

i was rereading. so let me ask you this. when the bearings wear out then the shaft walks longitudinally? and if so then does that mean that the seals leak as a result of that? or could the seals just be old and leaky?

It could be either or neither, I was trying to figure out why the cam would be walking. But, after seeing the set up for that cam sensor, a walking cam wouldn't cause that problem. The rear main might have taken a beating from the trans problem too. Just keep an eye on the leak and see how bad it gets, it may just leak a little bit, for a long time.

My house and garage here in Texas were built in the late 70's and at that time built under county codes which are less strict the City of Houston ones which we now fall under. My garage is 22' wide and 20' deep and the ceiling joists and rafters are all 2 x 6's!!! Most were showing signs of sagging only made worse by knots that had all but dried out and were cracking.

My man cave/ wood working shop conversion began by insulating and drywalling the walls followed by a major re-engineering of the ceiling. Replacing the sagging rafters was not an option and even if we had, the code would call for something like a 2 x 10 or 2 x 12 or some kind of laminated beam. So I used an idea from an article I read several years ago in Fine Homebuilding. We jacked up the joists as much as possible to straighten out the sag, as much as 1 1/2 inches in the center of the room in some places. Using 1/2 cdx plywood ripped into 6 inch strips my son and I heavily coated one side with wood glue, clamped in place and used drywall screws about every 8 inches in a zig zag pattern to create a sister side board, then we did the other side of the 2 x 6. After every joist was engineered with the glued plywood we attached 2 x 4's to the rafters in a truss pattern to spread the load to the roof which is a 4 sided pyramid shape.

Then we added R19 insulation and 5/8 inch drywall, damn that stuff is heavy! My son is out there now starting to tape it and float it. He was a dry waller in California before relocating here.

This is the ceiling from Wednesday top today, Saturday!

Finishing the hanging of the drywall and starting to tape the seams. My son will do 2 passes of hot mud which drys with in an hour and then a final skimming with topping mud. It can be sanded the next day and painted!

Well done, a lot of work but, worth it. Does it have hurricane clips?

5/8 Drywall, yikes! You must have a lot of faith in your new lam-beams. :haha:

No we didn't add clips to the existing garage but did to a shed addition I added at the back wall of the building. The garage is low and we are in a heavily wooded area of Houston so if hurricane force wind gusts ever got down to 8 ft off the ground we would be in serious trouble with our 2 story home and our neighbor's before it effected the garage.

My son recommended 5/8 as it is fire coded and is only about 18lbs heavier per sheet than a sheet of 1/2 would be and would be better for our uneven ceiling joists. We don't have snow to worry about for extra roof weight and I only plan on storing some light things in the small attic space. I thought the 5/8 4 x 8s were heavy and my son said I should try hanging 5/8 4 x 12's instead!

Drywall jacks are cheap to rent, and a wondrous thing to use. I had always thought they would be more trouble than they would be worth, and used the grunt & swear method. Then I was helping a guy last spring that insisted on using one, and I was very impressed... and kicking myself for the money I'd wasted on Tylenol all these years. :o

My man cave/ wood working shop conversion

Yeah Right , Until yer Wife sees How AWESOME it turns out , then it'll be a Yoga / Sewing / Gurl Cave !!!

Good Job so far !!

But 5/8 Sheet rock OVER FREAKEN HEAD ????!!!!

Dude do you have STOCK In Tylenol or sum such ??

very very nice chris!! major :thumb: which part of houston? conroe, woodlands, kingwood? did you by chance put down some decking in your storage area there?

My man cave/ wood working shop conversion

Yeah Right , Until yer Wife sees How AWESOME it turns out , then it'll be a Yoga / Sewing / Gurl Cave !!!

:D

very very nice chris!! major :thumb: which part of houston? conroe, woodlands, kingwood? did you by chance put down some decking in your storage area there?

We live in Kingwood and yes, the shed I attached to my garage has a raised floor built on treated 2 x 8's sitting on concrete blocks just above the ground.

We actually got shut down on this project for 2 weeks after my home owners association found out. They wanted to see plans including paint swatches and shingle samples and measurements to my property lines to show I was not on the utility easement at the back of my property. They eventually gave me permission and the storage shed is done!

Pink? Is that an insect treatment, or should I say anti-insect treatment?

Pink? Is that an insect treatment, or should I say anti-insect treatment?

That's what I wondered but it is actually just to designate these as pre-cut stud length which is 92 5/8 inch in length.

again, nice work! here at the track when we built the deck on our outside party area i wanted to use concrete blocks but we wound up driving treated steaks into the ground. yeah it's gonna rot only in a matter of time but that's what i was told to do so i did it *shrug*. i work just down the freeway from you at 59 and lauder. drive up from friendswood. :smack: at least until i can get back into engineering or aviation.

I am thinking about building a cabin and putting it on concrete pilings, there are some prefabs you can buy that have a cone shaped bottom that is under the ground. Do you think that would work well and last a long time? I was thinking if I put some rebarb in them and used some 25k pressure treated concrete they should hold up.

And this guy is da bomb.

http://www.askthebuilder.com/[YOUTUBE]qbomj8A3vDE[/YOUTUBE]

Killer !!!

Got the Kidos SCREAMING !!!

Or was that YOU ??

I am thinking about building a cabin and putting it on concrete pilings, there are some prefabs you can buy that have a cone shaped bottom that is under the ground. Do you think that would work well and last a long time? I was thinking if I put some rebarb in them and used some 25k pressure treated concrete they should hold up.

now that sounds like a fun project!

Jim, love the vid man! kudos!

Love Spencer's facemask. That's awesome. Looks like a fun ride. I have a friend on the ski patrol over there, and another friend used to be the Assistant Manager.

yeah, i love that mask. Ippy got it for him for xmas. he got her the cookie monster hat....and they also exchanged snuggies.

I want to take them skiing(learning) there. That's where I learned how when I was appx spencer's age. not that I ever was any good at it....

Got the drywall painted and the new lighting up. Then we moved most of the tools and tool chests back in. Doing a big sorting of stuff on the workbenches so excuse the mess! This a totally major change from the old unfinished garage!

helluva job man! looks great!!

Wow! That looks great, and you did it so fast.

I wanted a big flat screen TV but my wife only let me have the little 13 inch one that no one ever watches in our guest room...:(

Great clip Jim. Nice drywall Chris.

You don't want a flat screen in the garage. What if you were watching the ball game while using the saw or something?

I don't know. Just I'm trying to make you feel better. :)

but wait! use the Pomegranate Phone shown on

this page and your set. all you need are those gloves butchers and fishermen use so they don't cut their hands!

well we started another special project at work today. what this job calls for is to put in another car port aka party area. rather than do what we did with the last time where concrete footings were an afterthought...this time we are doing it right. first we of course measured everything out. the carport is 20' x 30'. the slab we formed today is 5" x 30'. tomorrow after the cement has cured we will remove the form and make the other slab. once that is complete, in about 10 days or so, the carport will be installed then it will be time to deck it. once we framed up the form and put 2 expansion joints in we then put one run of rebar in. should have really put two but one will suffice for this job. rebar re-enforces the concrete. 8 bags total. talk about a pain in the ass! mixing concrete with a shovel in a wheelbarrow sucks. trust me.

Visiting Paris and spent several hours at the Louvre wondering around with my wife who has never been there before. This is about my 6th trip so I decided to try to capture it in a different way than most of the tourists do.

I would caption these as:

1. Lovely garden statue but my home owner's association would never allow it!

2. If an erection lasts for more then 3 hours call a doctor or you will look this for the rest of your life!

3. Everyone has to take a picture of the Mona Lisa but I rather enjoyed taking pictures of everyone doing it.

4. Who needs to get up close when you can just view it on someone else's camera!

Finished the day and headed back to the Hilton. We told them it was our anniversary when we checked in so today they gave us fresh flowers, champagne and some kind of chocolate decadence!

Captions:

5. "Dad! Mom's going to be really pissed when she gets home and sees how drunk you are!"

6.. "Psssst! Did you just let a really stinky one fly?"

7. Our surprise.

8. Even though it was close to freezing we went out on the 7th floor balcony and set up a picture with the Eiffel Tower in the background.

Awwww....happy belated anniversary! Paris, what a nice vacation. :) And that's a very lovely surprise! I'd love me some of that yummy piece of chocolate!

i love paris. been many times. i could spend a month at the louvre. beautiful place! used to have a pic almost like the one you took of everyone taking a pic of the mona lisa. i lost over half my pictures in the bs from 5 years ago. enjoy your trip! oh and happy belated as well!

well we got the second form completed yesterday. when i arrived at work bobby, my boss and pilot bud, had already started working on dismantling the first form to reuse and make the second. you have to be careful with concrete. make sure you have given it enough time to "cure" before removing the form. otherwise you run the risk of chipping/breaking the concrete. i'm new to concrete work so i'm learning these lessons as i go. all i know for sure is this: mixing concrete with a shovel in a wheelbarrow sucks. really really sucks. it took 8 80lb bags for each form. we ordered the new carport yesterday and should arrive in 7 to 10 days. long enough for the concrete to thoroughly set. well i'm off to get ready for work. 14 hour day ahead.

ok so the car port was put in today. errr sunday morning. tuesday we will start decking it. pics of that to come. i'm rather proud of our concrete work here. here is how that part turned out.....

why am I not in paris like chris??????

must remedy this...

Paris is a wonderful city!

ok new project started at home today with OMG status already achieved. TERMITE DAMAGE FOUND!!!!! ugh...what was supposed to be a new shower now is looking like new walls too. and god knows what else. pics of the demo so far.....

Cool Now give it a good Spray of Bug spray ( Prolly dont Need it ,But Hey its Open ) and seal it up

Rember this ????

Man you need professionally bonded treatment for Termites or you will never sell the place in the future. Just saying....

yeah we will be treating it. actually come to think of it i believe the house was already treated. 6 to one half dozen the other. i'll check on that and see. well here is how far we got today at work with the deck. we went to lowes in Humble, Tx and bought 2 2x4x16's 63 2x4x10's to bring back to the track but also bought but will pick up later 63 2x6x12's (i think) for the decking. anyway we made alright progress today. we laid out the 2x4's for runners then cut up other 2x4's into 4 16" stakes and 2 12" to drive into the ground for anchor support on the runners. we got 6 of the 9 runners in today and weather permitting will finish the other 3 tomorrow and start decking to hopefully be finished by the weekend. we also still have to finish the electrical too.

your input/ideas wanted:

[YOUTUBE]d4RCX1u0sNY[/YOUTUBE]

ok while i was at work building the deck, paul was demoing the bathroom at home. the window framing has to be redone due to t-damage so it will be taken out and replaced. here's the latest....

oh the dead area behind the shower is going to be utilized. we will make the shower bigger (longer) and re plumb up the shower pipes.

Furdowns are a HANDY Place to run wires , Plumbing , Speaker wires for the Next room , etc ,,,,,

Pain in the ASS to sheetrock or tile But they Are Usefull

Furdowns are a HANDY Place to run wires , Plumbing , Speaker wires for the Next room , etc ,,,,,

Pain in the ASS to sheetrock or tile But they Are Usefull

true true. in this case however, that fluorescent light sucks. same fixture is in all three bathrooms. we don't like them so it's going bye bye.

Throw throw bulbs In the trash First , then the Fixture on top !!!

so leave the FD and mount new light there and not on the wall? that's an idea....

In My Opinion if the Furdown could be Potentially use full Leave it ,

if Not TRASH the Fucker !!

We Have a Furdown that runs down 2 wall of our Kitchen ,

1 of these walls backs up to the liveing room ( where the Tv and the such is )

it is SOOOOOO Easy to drop a wire ANY Where down that wall !!!

None of that Drill a Hole and HOPE its in the right spot , Hell I have a 12x12 ( Ish ) Cavity to work with ( SHUT UP YA Pervs !!!)

lol i'll leave that one alone zip! no in this case the FD has no potential. so yeah we're scrapping it. here are pics of a 2x4 removed. the little bastards were hungry i tell ya!!

that aint wood , its saw dust held together by sap !!

If things are THAT Bad you guys May want to Start Looking at Structural intgererty All to gather !!

as in Whats a Load bearing wall , where , and what is it Holding up !!!

oh hell. check this shit out.....lemme go grab a pic

or four. it may be hard to tell but check out the twist in this 2x4. there are foundation problems here too. a nightmare. but i do what i can do. do what i'm asked of. make recommendations and if they are taken they are. usually $ dictates what is done. budgets. too bad we don't have an oil company's budget.

today the wx was bad so i didn't go to work to work on the new deck. so instead i worked in the bathroom downstairs. the deeper we dug in the more t-damage we found. pic #4 below shows it best. in the upper right back corner i had to remove a section of 2x4 that was eaten away using the "duct tape" of electrical power tools. yep. a

sawzall. we reframed the window and replaced the eaten studs as well as put up most but not all insulation. the temp is dropping here tonight to the mid to upper 20's so that made it a little more important to get up.

oh yeah, almost forgot...paul did call the insurance company. not covered.

here is the PITA job of the day. the shower pan has to come out to make room for the one we are going to fabricate from concrete. back in the day when this pan was installed they used molten lead to seal the drain. basically that meant that you have to get down there with a hammer and screwdriver and dig that shit out. it took me all of 2 maybe 2.5 hours of hammering chiseling and digging but i got it done. once i was down far enough i used a bigger screwdriver to dig down the the base of the drain and get under the lead thereby allowing me to pry out the lead that was adhered to the pipe. once the pan was out i had to clean up the packing (dirt) that was under the old pan to clean it up for the concrete pan we are going to install. this process begins with making a curb form then pouring the concrete and let it set up for a day or so then once it's set we will put down the rubber pan and then tile it up.

demo is now almost complete. paul is toying with the idea of re-tiling the floor too since we already have gutted the entire bathroom.

and of course it's not a job unless you give a little blood to the project gods...

Oh There MUST be a Blood Sacrifice !!!

true there. tomorrow if i don't go in early to work on the new deck i have to re-route some romex. no big deal. in the upper corner you can see where the wiring went to power the light over the sink. since we removed the fur down i now have to drill 2 2x4's and pass the cable through them so that the drywall can mount up flush. still trying to decide where to mount the new light over the sink though. on the wall or on the ceiling? dunno. figure that out later.

I suggest the wall. I just like that look better. And don't forget to put in a light/vent fan over the shower and for Pete's sake, make sure the vent exhausts OUTSIDE! I've seen what can happen when the vent exhausts into the attic, a void or once even a dryer port.

Come summer, I may even have a few big projects to share such as shed/barn building. Help is always welcome too! :D

lol right! yeah we are putting in a fart fan. didn't even think about venting to the outside. will go mention that now.

last night i decided to move the electrical like previously stated. MAN did i ever cause a spark! i was working "hot" and while removing the staple holding the romex on i busted through the insulation and ZZZZZZZZZZZZZZZZZZAP! didn't get me though but sure was bright! :D

i like the wall idea too but paul wants a ceiling mount. oh well.

last night i decided to move the electrical like previously stated. MAN did i ever cause a spark! i was working "hot" and while removing the staple holding the romex on i busted through the insulation and ZZZZZZZZZZZZZZZZZZAP! didn't get me though but sure was bright! :D

:facepalm: And you want us to jump into your airplane for a sky trip? :headshake

Which was brighter, the spark...or you?

;)

oh most definitely the spark!

oh and hey! i must be a good pilot......i'm still alive! :D

This is true!

Actually, I would have total faith in your flying ability. I would, however, think you might turn to me and say "here, hold my beer and watch THIS!" Vroooooooooom. I'm fearless in the earthly mortal realm, though.

:lol:

ahhhh yes. the proverbial redneck famous last words... "HEY Y'ALL WATCH THIS!" splat.

You boys need a good fire! Imagine how fast you could build... I admire your grit though.

I'm sure this is a dumb question... but are you certain that's old termite damage? I hope you are treating the ground around the house with termite poison just to be safe, otherwise all your new work could get eaten away again in short order.

I'm sure this is a dumb question... but are you certain that's old termite damage? I hope you are treating the ground around the house with termite poison just to be safe, otherwise all your new work could get eaten away again in short order.

just got through doing just that. yesterday one of bobby's friends showed up at work. he's an exterminator. gave me some heavy duty shit to spray. i soaked the bathroom especially the hole in the concrete for the shower drain.

ok. we are finished for the night. you can see in one pic the termite treatment sprayed vvvvery generously around the hole in the house slab for shower drainage. this weekend while i was trying to not get mauled by go kart kids paul put in the shower wall framing. then the framing on the wall behind the commode/vanity wall. the pipes made him do the jigsaw puzzle 2x4s then tonight i re re-wired the ceiling circuits to facilitate our needs. paul did decide to go with a wall mount light like i had hoped he would.

Looking good.

Question: Those cut up vertical pieces seem to be supported only by the connection to the existing drywall and a little cantilevered action from that stud to the side. I don't really get it. Are they just something to hold the drywall/hardi screws for the new wall? Or are they supported by something solid that I can't see?

ahhh. I got to go take a nap right now...

yyyyeah. i don;t agree with this part of the installation. he needs to notch 2x4s (my apostrophe key doesn;work sometimes and i;m tired of pounding the shit out of it) and put it in there. i asked him about this and i got a mumble answer. errr one i cant remember right now. doesnt make sense to me either. not a load bearer so whatev......

Yeah, I'm sure it's fine. Not the way I'd do it, but the house isn't going to fall down or anything.

Yeah, I'm sure it's fine. Not the way I'd do it, but the house isn't going to fall down or anything.

actually it is a load wall now that i looked at it again but one stud isn;t going to make that much of a difference. but like you said glatt, the house isn;t going to fall down.

ok time to do some electrical work. remember to always make sure the circuit is off then verify using a voltage tester. most know this but the black wire is your HOT wire and the white one is the neutral. the bare wire is the ground wire, or sometimes it;s green. oh, and when you do test the circuit you should have somewhere in the neighborhood of 120 volts. on this circuit i have 121 but that;s alright.

after striping back the insulation on the wires you then twist them together. black to black white to white ground to ground then use wire nuts on the hot and neutral. it;s always good practice to then seal up the wire nut with electrical tape.

sorry for the somewhat fuzzy pictures. my crackberry is overdosing today.....

the cut outs for the fart fan and a/c duct were a tad off but will be alright because of the flanges on the vent covers. then in the back there is the shower light. the fart fan is on it;s own circuit because i did not want the fan to suck up steam from the shower since it;s not venting to anywhere but the ceiling. i know i know....i tried to tell him. vent to outside but eh.....anyway.

the garage let alone the house is a disaster area right now. here is the new vanity that we are installing. picked it up on what ladies?? yes, we picked it up....on sale! :D $100 bucks.

ugh....back at it. i can hear paul cussing in canadian all the way up here in my bedroom.

cussing in canadian

Ehh FUCK !!!

lmao yep! and the "awww you mother fucker, you piece of shit, get in there, ahhhh fuck all eh"

edit: now i'm saying that too. smashed my thumb with the hammer.

ugh....back at it. i can hear paul cussing in canadian all the way up here in my bedroom.

What's that all aboot? ;)

This is what we did to Kung Pao Kitty yesterday.

What did you do? Btw, that kitty is adorable!

(my apostrophe key doesn;work sometimes and i;m tired of pounding the shit out of it)

The noble apostropholon returns!

RAWR! I is a LION!

Oh, I see it now. Poor kitty!!!!

What's that all aboot? ;)

it;s aboot pronunciation.

"ahhhh facker! get in there ya whore! oh fack aff!"

he was trying to screw in sheetrock and kept missing the stud.

*snicker*

omg! kitty been in a fight with the clippers!!

The noble apostropholon returns!

indeed. i have to pound the crap out of that key to get it to work. lemme count here.....

' oh. sure. right. damn thing worked the first time. beh. gonna go grab pics of what we did this morning before i had to drive to work to do more decking.....

phone is seriously smoking crack right now. no pics. maybe later. i have a poker tournament now that i forgot i registered for so...more later.

light sucks with the light on in there and the crackberry really torches the pipe when the light is on. here;s a few pics of what was done this morning before i went in to work.

paul picked up a couple handy tools. he needed to buy a new battery for the drill but it;s cheaper to buy a new drill and get the battery with it. this is what he picked up. a small pistol grip drill and hackzawll by Milwaukee. neat little set cost 150 bones. i dig the charge light....

alright...while paul is sheetrocking the downstairs window in the bathroom i am starting the demo of the shower wall in the upstairs master bath. there is a leak back there that we finally found. remember earlier in this thread we did the floor in there.

demo is generally pretty easy and in most cases quick. total time on this was about a half hour. good news is there is no visible termite damage. the leak isn;t coming from where paul thought. it;s been a pain in the ass trying to find. i think, after going under the vanity and looking at the drain pipes, that that is where the leak is. the rubber gaskets are hard and rotten. now paul is considering taking the tub out completely and replacing it with an elongated shower pan. remains to be seen.

i was apprehensive about how to do the shower pan installation. getting the slope right and all. then i found this:

[YOUTUBE]fDFtzGNRpvs[/YOUTUBE]

now paul is considering taking the tub out completely and replacing it with an elongated shower pan. remains to be seen.

Tell him Dont do that , bath rooms with Only a Shower are considered 1/2 bath , he could Devalue his House , call a realtor

i told him what you said. makes sense though. so now we may just keep it in there. it will be a pita either way. replacing the gaskets or even taking the tub out entirely and hauling it down stairs would be a royal pita. i;d rather leave it in place and replace the gaskets.

alright. we went into overtime tonight. after supper we started pouring concrete. i had wanted to get a pic of the shower drain flange and the amount of distance from the floor to the bottom of the flange but paul started mixing concrete and i had to haul butt to help so i didn;t have my camera on me. anyway, there was about a 3 inch gap or more between the existing concrete and the bottom of the flange. i cut off one inch earlier today and recommended more but paul didn;t want to do that. well i finally convinced him. reasoning being we would loose depth of the finished floor if we left it the way it was. so i took off one more inch from the drain pipe then set the flange. we mixed 1 and 1/3 bag of quickcrete and floated in a floor. when doing this sort of thing you want the cement dry. add only enough water to make it moist then use a trowel and level it as best you can using a level. doesn;t have to be perfect. the installation kit we are using makes the slope fool proof.

now all we do is wait for the crete to cure. in this case we are only going to wait about an hour. then we will set the quick slope installation kit and pour the rest of the crete.

in these next pics, sort of another interactive if you will, we are looking and trying to decide what paint color we want for the walls. the tile is the tile that is going in the shower. i like the darker but the lighter colors also bring out contrast. any thoughts?

we hit a dead end tonight. the ring that goes around the drain is the wrong size. BUT we did get the rubber pan in. first we laid it out then tucked in the corners then located and punched through the drain bolts then put the flange on and tightened it down. after that it was cut to fit but make sure you don;t cut less than 3 inches from the floor. any folds that need to be made can be hidden by the drywall.

Don't the sheets have to glue together at the seams?

no, not in this case. it was like a 4 x 6 sheet of rubber basically. so you place it in and cut to fit and fold on the seams. at least that;s what we did here. i;m sure there are several ways to do this part of the job. first time doing it so maybe we half assed it. i dunno. more than one way to skin a cat. i figured the weight of the concrete and the mold resistant drywall being mounted would suffice. if there is a better or easier way that you know of please by all means let me know. we may be doing this again upstairs.

i took these pics before i had to leave for work. paul went and got the correct ring so we could cut and mount the slope sticks. then he poured in the concrete.

then while he was doing that i was finishing up the deck installation at work. to space the 2x6x10 and 12;s i used nails and put them between them to give room for weather. the boards will expand and contract in hot and cold weather respectively so you want a little wiggle room. then for the boards that were slightly warped i stuck a crowbar in the ground and leaned on it while drilling in the decking screws. after the decking was complete i ran a chalk line down the sides and trimmed off the excess with a circular saw.

You get a lot accomplished. I'm impressed.

ty, i try. all it really is though is focus. well, energy too, lots and lots of energy :)

i;m glad i finished that deck yesterday because there are 10 parties booked for today. we thought it was 11 but the manager miscounted. either way 10 parties is a lot and several of them overlap. i betcha by sunset i will have completed my 2 step videos on the proper way a go kart ride should go and the "omfg what are you doing" way. now that is gonna be a fun thread! :D

Ya know, that bathroom job started out with a dripping tap. We'll just replace the washer, they said, but then they saw something else that needed doing while they were there. One thing leads to another ...

yep and that;s what i;m afraid of upstairs. to be honest i just got home from work and didn;t even go look in the downstairs bathroom. i;m exhausted, i got nailed by a kid tonight and almost broke, what felt like anyway, my right foot. got sandwiched between two cars. will have vid later for the thread i;m creating. on a motrin and beer binge, errrr for a whole beer then bed. the new party area was used and rented today. a plus there. we were the busiest ever in the history of the go kart track! we had a line of more than 50 people waiting to ride from 1 o;clock until about 11. gonna hit the rack. later peeps.

the finished party area. done. finished. finis. hoàn thành. завершенный. fertig.

paul got quite a bit done this weekend in the bathroom while i was playing frogger in go kart traffic. he got all the sheet rock hung and is now tiling the shower.....

he did take pics along the way though. all i have to do is get them off his camera and post them. will do it sometime today after i run errands.

paul said i was cutting too slow. f-that! i like my fingers!!!!

[YOUTUBE]2XMq1Xlq1Ws[/YOUTUBE]

also here is some of the progress we have made today. so much for my day off.

tyty it;s coming together slowly but coming together....

going back a bit...these are some pics paul took over the weekend while i was at work...

then this is how far he got on the tile today. then i;m off to homo depot for a paint pan and liner so i can prime the sheet rock....

alright so i got back from homo depot and started priming. messy job it is i tell ya, lol! but i got;er done.....

then the white boy just got whiter! i forgot i had my prescription sunglasses on my head and they got a sprinkle too. pita cleaning them off without scratching them. i didn;t want to use thinner on them for fear it would f;em up....

I HATE Painting !!!

So much so Both houses we have owned we got sided ,

Carol does the Painting in side , Ill help prep , and clean up , and Get Hard to reach spots , but the rest is Hers !!

yeah painting blows. but at least i can do it. wall tile? no. i can;t wall tile. i help prep and will mud and cut the tiles, but paul places them. at least the ones going up the wall. floor? no problem. but the wall? no.

alright. here is the progress made over the weekend. the shower is tiled and we are now grouting with non-sanded grout. i like the contrast from the shower floor to the wall..what do you think? also i mounted the light that goes over the vanity as well. floor tile in too.

Thats looking good man ,

But ya got a blub out dude !!!

Thats looking good man ,

But ya got a blub out dude !!!

It's early, and I'm not a morning person. I just went googling to figure out what "blub out" meant. I figured it must be an industry term. :blush:

It's early, and I'm not a morning person. I just went googling to figure out what "blub out" meant. I figured it must be an industry term. :blush:

:lol: I thought blubbing in reference to the pubble of water, then considered the source......

I love that tile in the shower! I will have to remember that when I build my next house.

i;ve been getting home late working 12 hour plus sometimes days building panels. here is where paul is with the bathroom... i particularly like the tile, like merc, and the paint scheme. still a lot more to go but he;s making the best progress he can without me there to help him....

now here;s what i;ve been up to all week. i could bitch slap the designer that designed these panels. they left out several key electrical components in the drawings that set us back a days work. see, they knew that they had the parts to go in the panel but did not allow for space. we had to remount the wire ways, called panduit in this case - the manufacturer, and terminal strip din rails - the metal thingies that the terminal blocks, fuses and other components fasten to on the back plate. anyway, here are some pics today while i was wiring panel #1. started it after lunch and am almost finished with it. another wireman needed the drawings i had to complete his panel so i gave him them and started on panel #3.

oh, and as far as the pretty wire colors? black in this case is 480 volt, red is 120, blue is 24 vdc, white is 120 neutral, and white/blue 24 neg. oh and green is ground.

Cool !!

So Is the Ethernet for comm or I/O ??

been busy and not been around too much but here is what we have at the house. well as of yesterday. it;s late and i haven;t ventured into the bathroom tonight to check progress. the original vanity had the pluming holes on the wrong side of the rear panels so paul returned it and got imo a better looking one.

then this last week at work someone laid down a foundation for a BBQ pit for the new party area. when i got to work today me and RC mounted the thing. then later ronnie broke it in by cooking fajitas for the staff!

Separate woodbox would've been nice.

On the other hand, they don't let us do any kind of BBQ at the Sears tower.

Separate woodbox would've been nice.

On the other hand, they don't let us do any kind of BBQ at the Sears tower.

Yeah i suggested that but oh well...

Edit: damn you autocorrect!!

I like that bathroom tile. The wall colors look just like my kitchen.

I like that bathroom tile. The wall colors look just like my kitchen.

good taste in colors then! :)

ok here it is! the curved shower rod is a real nice touch. i think overall this turned out really well. (oh and for the neat freaks, yeah we lost the electrical outlet/switch covers and hafta go get replacements at homo depot.

Nice! Looks really good. Good work!

Looks Great !!!

Those Curved curton rods are cool

oooooooooooops. we gotta bust up tile and lay concrete. the shower pan is not sloped correctly. if you look reeeeeal close at the pan pictures you can tell that it is lower than the rest of the shower in the upper left hand corner. what happened was that paul ran out of concrete and hoped all would be good. nope. so gotta fix that. we tried the shower tonight, not together mind you, and found out that the pan has a low spot.

BuuuuuuuMMMMeeeRRRR !!!!

I Hate redoing a Project !!!

yeah true....but it;s only 2 tiles so......

it was a real pita. first off i mixed the quick set with too much water so it was a pain to work with. notice in the second pic the level bubble showing slope away from the drain. after i put down the quick set and let it cure for an hour and a half or so i was able to come back in and mold a slope as seen by the bubble in the last pic. now we let it dry overnight then relay the tiles back in.

ok. today i put down the tool belt and picked up an airplane! THANK GAWD! here are some snippets from today. i met up with bobby at work and he brought his zr-1 vette! nice ride!

[YOUTUBE]u-lcoi4aQOM[/YOUTUBE]

then engine start up....

[YOUTUBE]KPcWahTPS1o[/YOUTUBE]

then take off from KDWH

[YOUTUBE]Xn8ADb4GaS8[/YOUTUBE]

bobby landing at KCLL where we had an excellent lunch at

Dixie Chicken

[YOUTUBE]G5xAj-x0xrQ[/YOUTUBE]

and finally my landing at KDWH. bobby flew the leg up there and i flew the leg back so we could both get stick time.

[YOUTUBE]AjEhAUBYrZU[/YOUTUBE]

all around. it was a great day to fly.

Therapeutic air time. :thumb:

Therapeutic air time. :thumb:

yessir. yes indeed it was!

I vote this thread, the best thread ever.

one thing i forgot to mention about that flight was this. birds. BIG birds. after we took off from KCLL about 7 miles southeast of the airport at 2,000 ft. was a flock of turkey buzzards. about 15 to 20 of them. damn near hit at least 5 of 'em. had to do some fancy stick n rudder to avoid them. chopped the throttle to idle and went into a left hand rollover dive then recovered when we were below them by a couple hundred feet. scary and fun all at the same time. that's one of the reasons i love to fly. every flight is different. flying to me is almost as good as sex! oh, and i did tell air traffic control (aka atc) about the birds and their location because there was incoming traffic into college station including continental express.

do those flocks fly at night?

do those flocks fly at night?

I know geese do. Not so sure about buzzards though.

[YOUTUBEWIDE]hR1I8jYTq3Q[/YOUTUBEWIDE]

Well That Sucked , But I Did learn some thing though

Shark bite connector Dont fit PVC

looks like you had fun today! go into more detail. i don't know plumbing all that well.....

did ya see the hole in the Valve ? I still have NO Idea what that was there for ( the valve that is )

So we removed Patio stones , 12x12 cement pavers , dug down remover More Pavers , dug down some more , i felt around in to hole , found what felt like a Valve handle , dug some more , Bailed out water , Shit its a valve , Shit there is Water Squirting Out of the Top side of the valve Ran and turned OFF the water Got a pipe cutter , cut out the Fucking Valve I cut it close so as to Not have to add any pipe ( more on that in a sec) , went to Lowes , discussed the options with Carol , we had wanted a faucet in the back yard , so Hell No time like the present , got the faucet a 3/4 T and 2 3/4 straight fittings , i knew I would have to trim the existing pipe to fit , so No Biggie ,Right

Well when I started trying to fit this all togather I hear SNAP , and Im neeling there with about 6" of copper pipe connected to about 6" of Pvc in my habd , the water line Into the house is copper and they had connected a section of copper to the PVC to add the valve i guess , Shit , so hi ho hi ho Back to Lowes I go , get a piece of 3/4" copper pipe and another fitting , Measure the pipe i need takeing into account the fittings , cut the Pipe , push the fitting on said Pipe , push this into the T on the new faucet , shit the fitting wont fit on the PVC , Must be 1" , so Back to Lowes , snag a 3/4"to 1" fitting , Now the fitting wont Snug down on the Pvc Shit !!! Back to lowes with a Small Piece of the PVC , Dude explains that PVC is measured ID ( inside diameter ) copper is measured OD ( Out side diameter ) BS I say , Here Let me show you , and slides the Piece of PVC Over a piece of 3/4" copper , Well Ya learn something new Every day , so what do I do ??

I explain what im doing to him , he gets a pvc fitting that will screw Into a Union and 1 for the copper side as well ,

thus the pic and the comment that that sucked !!!

Looking mighty fine, zipper, did you lose some weight?

i don't know plumbing all that well.....

1. Water runs downhill.

2. Payday is Friday.

3. Don't put your fingers in your mouth.

Then there's this:

http://www.theonion.com/articles/when-you-hire-union-plumbers-you-hire-trained-prof,18853/trial and error zip. that's why i asked for clarification. i might have to do the same someday or maybe another cellarite. so if we do have to do said job we can come here and/or pm the "project manager"

hmmm maybe i should become a non-licensed plumber!

Did you get to the end of the article?

One last word of wisdom: If you hire an electrician, union or otherwise, he's going to fuck your wife right in the ass and send you the pictures.

Nothing you can do about that.

:eek:

I don't know about the project mngr thing ,

but im willing to throw in my 2 cents

Feetz I Used to be an electrician ;)

Did you get to the end of the article?

:eek:

oh ok this part:

One last word of wisdom: If you hire an electrician, union or otherwise, he's going to fuck your wife right in the ass and send you the pictures.

Nothing you can do about that.

oh the tighter the better!

shut up sheldon. :D

I don't know about the project mngr thing ,

but im willing to throw in my 2 cents

Feetz I Used to be an electrician ;)

I'll have to check out your flickr page again!

here is a brew that i picked up yesterday at spec's liquor store called "mississippi mud" like the bottle, like the flavor too! good brew! will be buying more of it in the future!

oops. meant to post this elsewhere...DOH! oh well. and i ain't even drunk! lmao! (thank gawd!)

i wish i'd of taken pictures but today i fixed the honda 4-trax four wheeler we use regularly at work. you see it's like this. a while back, almost 8 months ago the starter switch burned up. actually i think it was longer than that. more like 2 years ago. anyway, it was rigged up where the starter was wired from the battery to the switch to the starter. well that won't work. what happens is this. the switch cannot handle the amperage so it burns up. could be two starts could be 20. never can tell. well for the last 6 weeks or so i have been pushing to wire this up back right. in other words, wire in a relay like it should be. then what happens is this: you push the starter button. the starter button is wired to the coil. the coil energizes then closes the starter contact therefore bypassing the load that was going through the switch. (helllllloooooo! that's the way it came from the factory!) so anyway, i found out today that the relay in the quad is new. ronnie just didn't know how to wire it up so he bypassed it. the thing is a piece of shit but it works and it works well. for whatever reason the original starter button was 86'ed. i opened up the housing and the wires were cut. short. no way to rewire it. not that i saw anyway. not without taking the complete thing apart. so here's what i did. i wired the new switch into the coil. then spliced in the negative to the return wire. then i ran a wire from the hot through the switch and on to the relay coil. for whatever reason, no wiring diagram of the scooter so had to improvise with a volt meter testing continuity, got it to where i could energize the coil. now second problem aroused. the starter positive post is jacked up. took me several tries to make it work. adjusted the nut to get a deeper penetration into the starter. prolly needs a new starter. duct tape and bailing wire be damned. the thing works. will try and take pictures of it tomorrow.

ok so. here are pics of the finished job on the 4 wheeler at work. pic1 shows the relay. pic2 is the wire i connected to the battery positive terminal. the other end of the wire was at the starter button the other was connected to the relay plug you see here in pic4. pic 3 was splicing in the negative. and finally, pic5 showing the starter push button.

totally forgot to resize the damn pics, sorry guys

Pretty typical day after a Bad ass Thunder storm last nite ,

the scale ( Under the counter ) the Main PCB ( the brains ) caught a Bit of a Sparkle , still weighed but that was All , No comm( to PC , or any of the score boards ) , No I/O ( traffic Lights ), first time this has happened in 6+ years

solution , replace the main Pcb , load the Custom Program and all the setup and cal data I backed up on the PC (and My Laptop )

Oh and I Included a Pic of the Palatial Shack right Next to the Radiation Det , heat and AC , Insulation

that was My Afternoon , how was yours ??

good job bro!

now this.

sumbitchmotherfuckinshitifuckedupagain.

pics soon of body work on a 2001 ford f-150. pole was in my blind spot and i checked to see if it was there. it was. new project soon. hopefully next week or so.

ok, here is a small taste of one of the many cabinets i've been working on. today i started on this one. it's a 40 ckt (circuit) heat trace panel that requires 208v(olts). there are 40 ckts dedicated to the heat tracing, which by the way is where a pipe has to be heated to whatever temperature for whatever reason, this panel controls the temperature via the heating elements and the RTD's (resistance temperature detection). first thing is to take the drawings for the panel and check the BOM or bill of material. next make sure everything is mounted where it's supposed to be and the right parts were used. next is making sure that the equipment is tight and snug. after that you do a point to point wire inspection and ohm them out to make sure all connections are correct and that the termination points are not frayed. then you take make shift RTD's and insert them into the RTD terminals as seen on the left side of the panel. the fake RTD's are the maroon looking thingamabobs. after that, hook up service power and power up the panel load the applicable software and test every heat trace circuit. after all checks out and problems fixed, remove fake RTD's, heat shrink the wire tags, blow shop air throughout the panel then vacuum out the bottom basin. done.

in most cases. this panel has not only an air conditioner (on the right side panel) but also has what's called purge air. what that is is this: the panel is going in a hazardous location. ie there are flammable gases present so they hook the panel up to an air line and have positive pressure in it to prevent any of the ambient outside air to enter the enclosure.

i like my job. :)

Purged air SSSSSSSUUUUCCKKKKSSS !!

Scary when you have to By pass it with an extension cord that you have to cut the end off so you can work inside the panel in a haz area ,

Good job

Ok so rember the washed out slanted Pool ??

Dscf7353

Dscf7353 by

zippyt, on Flickr

Well I drained , dissambled and Moved that Heavy Mother F(Watch Yo Mouth !!!

this Morning I started leveling and installing pavers to Harden the Places where the Steel support poles touch the ground , in 100 f heat no less

Dscf7365

Dscf7365 by

zippyt, on Flickr

DSCF7362

DSCF7362 by

zippyt, on Flickr

DSCF7363

DSCF7363 by

zippyt, on Flickr

Wash out and sink AGAIN byotch !!!!!

I dare Ya !!!

There's an irony to working your ass off in that heat on your pool and not being able to cool off in it later.

It's damn ironic, I tell ya.

Ya Tell me about it !!!

I went thru 3 2 liter Hydration packs today and I am Only about half way done setting the pavers , much less leveling the sand , much less setting the Pool BACK Up , Much Less Filling the 6000 gallon Fucker ( it takes 24 SOLID hrs ) !!!

It'll be worth it though

I went thru 3 2 liter Hydration packs today...

Oh yeah? I didn't know you could get Spaten in two liter bottles, SUH WEET!

;)

It will be worth it.

Today I finished a bathroom remodeling job for the bathroom that my step son's 5 children share in their home. They needed 2 sinks and the paint and tile needed updating. Two sinks required plumbing modifications and a new vanity and counter top. I also had to replace the rusted toilet flange and install a new toilet as the old one was cracked and leaking.

Shot 1 Pre-demo

Shot 2 plumbing mods

Shot 3 vanity construction

Shot 4 project completed!

Very nice! I wish you were my stepdad.

Also, you need some caulk around those sinks. :)

Thanks and yes, I applied a bead of caulk to the rim of the hole to seal the sink to the counter and today I used a white silicone and filled the small space where the outer edge of the sink meets the counter surface.

Excellent work Chris.

I too did a bathroom remodel over the last few days. Stripped the room to bare wall and sub flooring. Skim-coated the walls on day one, then painted on day two. Day three was lighting, Luan, vanity & toilet installed along with matching brushed nickel accessories. I'm beat. Gotta finish some caulking - I'll do that tom. I don't like the counter top, so I'm gonna order a granite piece and that should finish the job.

Gorgeous bathroom, and I love that shower curtain!

Damn Chris! "Oh, yeah I just knocked out this vanity. Still had time for a few rounds of golf that afternoon"

Great job!

very nice!!!

i have a project coming up soon. automotive. replacing my a/c in the Fixed Or Repaired Daily again. stay tuned. i'm busy so i have to make time to do this. will be before the end of the month as the warranty expires then.

There's an irony to working your ass off in that heat on your pool and not being able to cool off in it later.

Its later ,

The Pools not Full yet but its deep enough in can float and drink a cold beer

DSCF7368

DSCF7368 by

zippyt, on Flickr

Hahah.....Looks like you're enjoying yourself. :D

Much Less Filling the 6000 gallon Fucker ( it takes 24 SOLID hrs ) !!!

Yikes. Glad I don't have your water bill.

[YOUTUBE]27u35P06XsU[/YOUTUBE]

sweeet zip!!!

here's a couple vids from flying today....one is landing at cleveland muni (texas y'all not ohio) and the other lake livingston. then later i'll add one of me being a little goofy (but not too much) :)

[YOUTUBE]8LV-7_w9nEY[/YOUTUBE]

[YOUTUBE]WDRv8-RSRTY[/YOUTUBE]

flying over lake livingston

[YOUTUBE]fom1AeZmr_4[/YOUTUBE]

[YOUTUBE]lHvvs2-UMjs[/YOUTUBE]

kthxbai!

In a week or so we are headed Back to Fla ,

its a 1/2-3/4 mile walk to the beach from our cabin

I have been looking at carts to carry coolers chairs Etc,,,,

most of them are $2-300 !!!!

So thanks to the wounders of the Net i found some drawings of a cart made from PVC

so fro about $100 worth of Pipe , Pipe fittings, and wheels

I made my own , Check it out !!!!

cart1

cart1 by

zippyt, on Flickr

This thing will hold 2 full size coolers !!

yes I still need to tighten up the axles and glue a few Pieces on the Handle , But it works Great !!!!

Today I spent several hours scanning pictures from my mother's WWII photo album. Some you may remember I have mentioned that my mother was in the OSS and went out to India and on to China with Julia Child and also worked with Paul Child. In Chungking she met my father who was a major in Britain's MI9 unit.

I just finished reading Jennet Conant's new book, "A Covert Affair, Julia and Paul Child in the OSS". I contributed material for the book from mother's war letters and a diary that she kept, written in shorthand! Anyway, it got me thinking that maybe I will try to put something together as I have hundreds of letters and photographs. Even if is just for me and my family it would be a way of sharing the information.

So here are some of today's images:

1. My mother at her desk where she worked as the secretary to Col. Dick Hepner who was Chief of the OSS Detachment 404. note the barbed wire covering the window for security.

2. Paul Child, another officer and Col Hepner working on war maps.

3. Julia Child with some other OSS staff in Kandy, Ceylon.

4. My mom, the caption on the back says "crossing the Yangtze by ferry." I love the very 40's sheik V-neck sweater, nice permed hair and sunglasses. She grew up on a farm in Minnesota and after the war never moved back, she and my dad moved to NY and loved to travel from then on!

In the second picture, w/Mr.'s Child and Hepner, I feel like I know what that is on the table. No, not the bowl! I just can't pull it out of my memory. I want to say it's a radio, but, that doesn't feel right...musta killed that brain cell at some point.

Even the pictures you didn't take are cool.

Oh, yeah, I see. Did it take two hands, one for the talking hole and one for the hearing hole? Or what?

I also just now noticed the padlock on the jeep hood.

It's just like a normal 'phone. Follow the lead, you can just make out the top of the handset on the side facing away from the camera.

Ima Dumas. I see now. I thought the cord from receiver to handset was a rope for carrying it.:lol2

Also, looks (from this stolen Flickr pic) like the bells are turned upside down, that threw me, too.

My mind gets a grip on things like this and won't let go sometimes. Thanks for straightening me out.

They are great pictures. This is what's great about the internet. Now people wanting to research Julia Child in WWII can see these.

They are great pictures. This is what's great about the internet. Now people wanting to research dumbasses who don't know what a phone is can see these.

FIFY.

The bells are inverted to function as ash trays.

Shed construction begins tomorrow. Pictures will be taken this time.

Stay tuned!

I do NOT believe this! It hasn't rained in months. So I get to laying the foundation and it bloody well RAINS!

Now it's too hot and humid to work. Oh well, tomorrow's another day!

Here's a pic of what I did a few days ago...the rock is almost big as a golf ball.

What a python, what an anaconda, what an --- inchworm?

Thats not a rock, that's a meteorite.

That's not a python anaconda inchworm, that's an Alien tentacle!

Thats not a rock, that's a meteorite.

That's not a python anaconda inchworm, that's an Alien tentacle!

Wait, what are we watching here, Star Wars, or Japanese porn?

Wait, Japanese Star Wars Porn!

the birth of a meme!

....4. My mom, the caption on the back says "crossing the Yangtze by ferry." I love the very 40's sheik V-neck sweater, nice permed hair and sunglasses. She grew up on a farm in Minnesota and after the war never moved back, she and my dad moved to NY and loved to travel from then on!

You can't expect such a classy dame, that's seen the Elephant, to go back to the farm. :headshake

Wait, MN? When I saw the first picture, I thought she had a beautiful smile that reminded me of Betty White. Rose Nylund was patterned after your Mom?

This stuff should be in the National Archives or Smithsonian. Antiques Road show would call them, "National Treasures", and I'd wholeheartedly agree.

Thanks a million for sharing them. :notworthy

the birth of a meme!

[scene in garbage compactor; tentacle grabs someone's foot]

Han Solo: I've seen enough hentai ...

I'm calling the shed project complete. I am far too tired to post pictures tonight.

I'll try tomorrow after running errands.

As I promised, here is a photo diary of my shed build project. It took three days of hot, sweaty toil but it's done!

This first photo shows the beginning. Boxes of parts staged at the site.

link

The second photo shows the frame of the foundation built and levelled.

link

The third photo shows the foundation completed with my friend Anne driving in the last screws (yes, I used the proper deck screws for PT lumber).

link

Photo four shows the floor of the shed laid out and assembled and connected. Thus ended Day One of the project.

link

Day Two began bright and early to beat some of the brutal Texas heat.

Photo five shows the walls in place. The directions made it look SO easy! Just insert tab A into Slot B and snap into place. HAH!

link

Photo six shows the major roof panels in place. This ended Day Two.

link

Day Three opened early also. By noon the temperatures are above 100 degrees, requiring frequent cool off breaks and about three liters of ice water each day.

Photo seven shows the more of the roof and the doors installed.

link

Photo eight shows the end product after the last roof parts, skylights and smaller things like shutters in place. The shed has been shimmed to allow the doors to open and latch closed again, the windows to open and all the roof vents and screens installed.

link

I wish I could get the images to appear in the post like everyone else gets but I don't think I'm doing something right. All I get are tags.

Apologies to everyone for all the clicking.

Next time we order something like this, I will refuse to assemble it until the spring or fall.

Wow. That looks like a lot of work. Worth it though. Well done!

okie dokie. here we go again. the other day i went and bought a new dishwasher as ours died about a year and a half ago. i forgot to take pics of the removal of the old one but here is the installation of the new one. i took basic step by step pics to hopefully show someone that this is a project that is relatively easy, albeit could be difficult depending on your ability to turn wrenches, hammer to fit and paint to match. the washer was delivered this morning and right out of the box i saw that i was going to 1. have to go to home depot and buy a 3/4" to 3/8" elbow to hook up the water line and 2. improvise on hooking up the electrical. i improvised using a spare computer cord. i cut the end off and stripped it back about 1.5" - 2" or so then stripped back the 3 conductors to connect in the junction box under the washer. after twisting the wires (remember, black is the hot wire and white is the neutral) i used wire nuts and electrical tape to secure the nuts so they wont come loose through vibration of the unit. it's always a good idea to tape them regardless. after securing the electrical cord and attaching the drain hose extension i positioned the unit in it's little cubby hole but not all the way as to give room to work/connect shit. i fed the drain hose through the side of the cabinets and attached the hose to the disposal using a hose clamp. next connect the water feed to the unit. oh, don't forget to use Teflon tape on the fittings. after connecting, turn the water valve on and check for leaks now. it would suck to complete the installation then have to take it out because it leaks. after checking that push the unit in place an make sure it's level. after that secure the unit to the counter top and take the washer for a test run!

eta: oh yeah, don't forget to hook up the ground wire (green) to the unit junction box.

well done cept you need a bushing or romex fitting for the cord going thru the box knock out

Well done plt! I agree with zippy, put some kind of protection for that electrical cord going through that sheet metal hole, eh?

I also see you're getting better with that camera including some left handed shots. Nice work!

yeah i'm going to go to home depot and get a bushing to put in there. i did think about that (after i'd already gone to home depot) when i was hooking up the cord.

thanks BigV i am doing a smidgen better with it. in january Dr. Froth (a member here that lurks mostly) had a concert and i ran all over the place from front stage to backstage snapping photos. i think i have them public on my facebook....

I'm calling the shed project complete. I am far too tired to post pictures tonight.

I'll try tomorrow after running errands.

thanks for sharing! great job!!

Not the way i wanted to spend an easter morning !!!!

I was pouring a cup of coffie this morning bare footed ,

suddenly my foot was wet

" WTF !!!!!!"

Looked at the bace board , wet , FUCK !!!!!

looked under the sink , WET, FFFUUUUUCCCCKKKKKK !!!!

and it had been wet for a while , FUCK !!!!!

So I grabbed a hammer and a pry bar and started stripping wet MDF board away ( why do they even make that shit ????? it USELESS !!!)

under the kitchen cabnets

DSCF7694

DSCF7694 by

zippyt, on Flickr

DSCF7695

DSCF7695 by

zippyt, on Flickr

Fans UP !!!

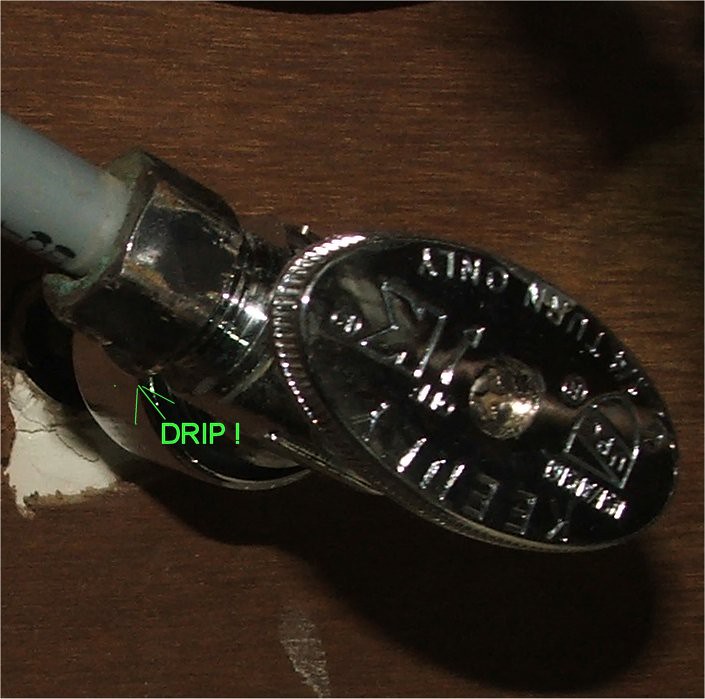

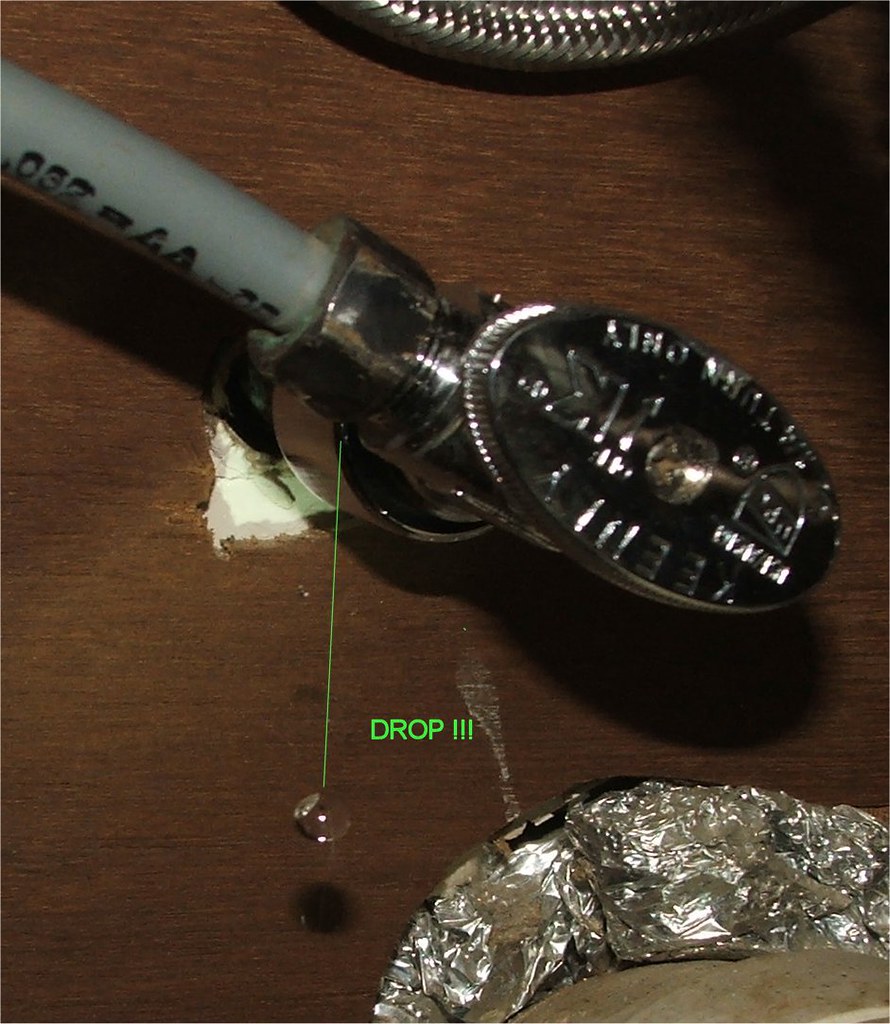

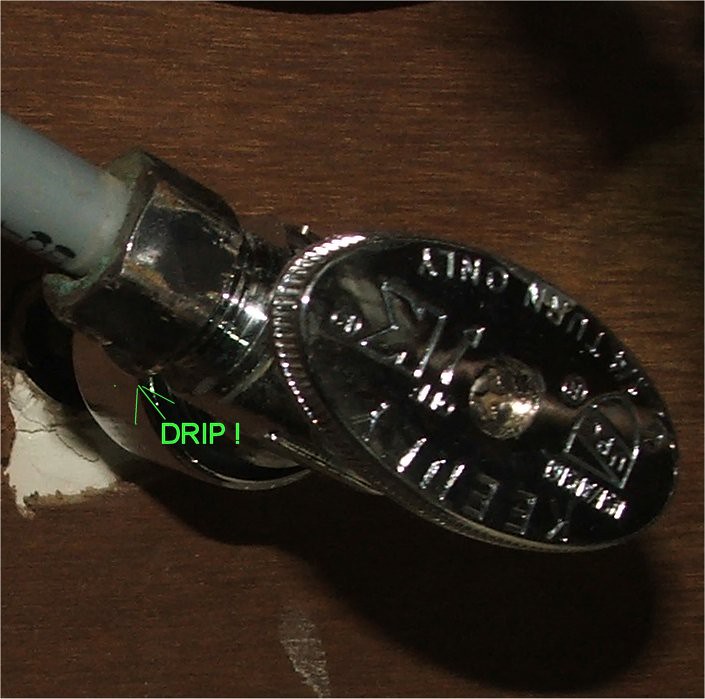

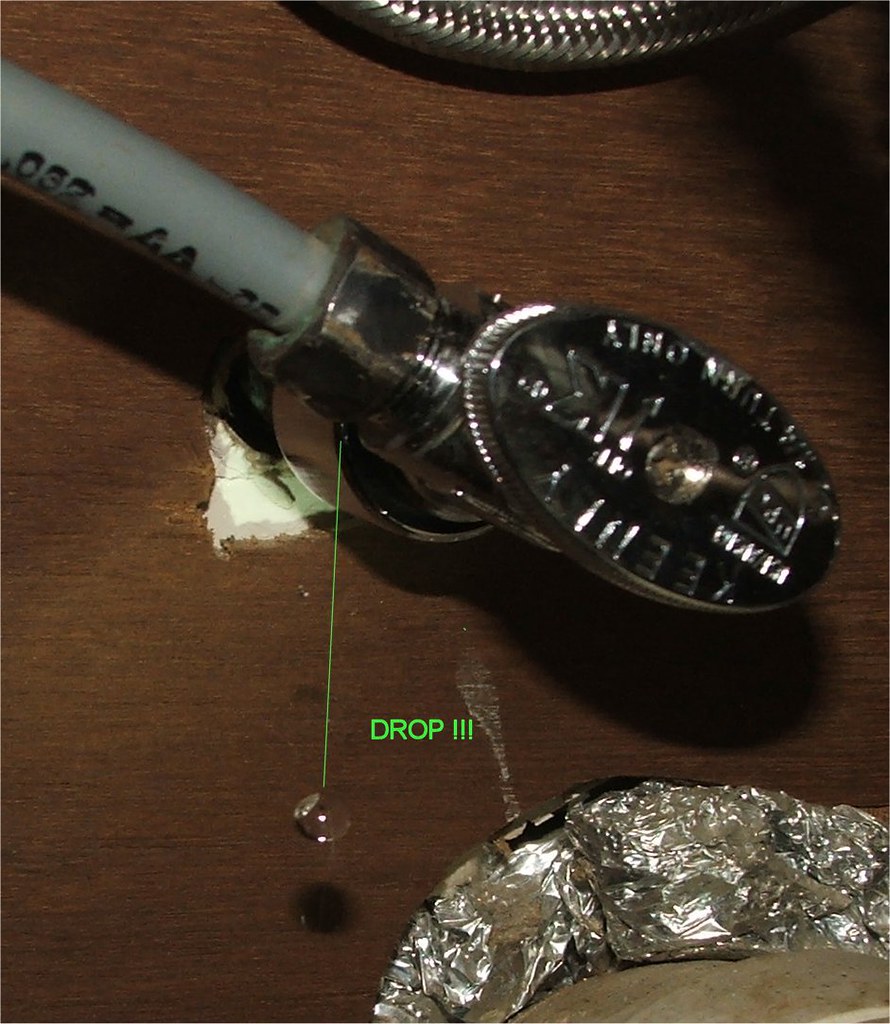

Here's the Leaken Byotch that caused this !

DSCF7698

DSCF7698 by

zippyt, on Flickr

And heres what it did ,

DSCF7702

DSCF7702 by

zippyt, on Flickr

DSCF7703

DSCF7703 by

zippyt, on Flickr

New fitting in place , but the pic i took to show you all , well i saw a small drip

DSCF7705

DSCF7705 by

zippyt, on Flickr

so i thaught i was done , but well i guess i have to mess with it a LITTLE More

tape measure? check!

spatula? check!

shot of whiskey? CHECK!

ugh that Shot is bacon greese ,

take a shot ifn you want ,

but i think it would be a Little thick going down

here is the drip and drop , hard to see untill i looked at it full screen

drip

drip by

zippyt, on Flickr

drop

drop

drop by

zippyt, on Flickr